John Deere 9800 forage harvester: Powerful and economical

By Georg Horst Schuchmann, DLG Test Centre Technology and Resources

The 9000 forage harvester series not only features a 24.2-litre V12 diesel engine from Liebherr in the three top models, but has also been completely trimmed for even higher throughput. The developers in Zweibrücken set themselves the goal of achieving a higher throughput per horsepower and at the same time reducing the specific fuel consumption per tonne of chopped material.

New engine - modified design

Like John Deere's own 13.5-litre six-cylinder engine with 625 hp installed in the "small" 9600 forage harvester, the Liebherr twelve-cylinder engine (Fig. 1) also complies with the current Euro IV or Tier 4final emissions standards. The specifications of the Euro V emission stage, which applies to engine outputs from 760 hp, are achieved with SCR catalytic converter and AdBlue injection. A special feature of the Liebherr engine is the design of all units and flow components for efficient operation at low engine speeds. This means a lower nominal speed of 1,800 min-1, sufficient torque reserves even below 1,400 min-1 and an efficiency concept that allows all machine sections to operate continuously at engine speeds of approx. 1,500 min-1. It should be obvious even to the layman that engine outputs close to the 1,000 hp limit also require a drive train that is stronger than that of the 8000 series and the construction of an appropriately designed main frame.

The 9700, 9800 and 9900 models have an 830 mm wide prepress channel with four prepress rollers that pass the crop as evenly as possible to the knife drum. The John Deere 9800 forage harvester used in the DLG test was equipped with a 12-row Kemper 490plus front attachment with a working width of 9 m and six large intake drums. The knife drum was fitted with 64 knives, covering a range of theoretical chop lengths from 3-14 mm. If half the set of knives is removed, it is possible to chop up to 28 mm. The grain processor, which was also newly developed, ensures that the grains are broken down reliably with a gap width of 2 mm.

Throughput, fuel consumption and chop quality

Forage harvesters are usually tested in the field by the DLG in the individual criteria "Functional test in maize" or "Functional test in grass" and, if they pass the test successfully, they are DLG APPROVED in these criteria. The functional test carried out with the John Deere shredder includes measurements of throughput, consumption - specified as specific consumption per tonne of harvested material - and technical shredding quality. The measurements must be carried out in at least two different dry matter content layers (DM content layers, here 27 % to 32 % DM and 37 % to 43 % DM) on selected silage maize fields that are as homogeneous as possible. In addition, different test variants are carried out at standard driving speeds and chop length settings, in this case 4 mm, 7 mm and 12 mm. The basic setting of the forage harvester is adapted to the respective harvesting conditions on site in the DLG functional test. The tests to determine throughput and fuel consumption were carried out in northern Italy in southern Lombardy, a typical high-yield region, in order to be able to exploit the performance potential of the forage harvester as far as possible. During the measurements in Italy, the dry matter contents of the stands were between 31.4 % and 37.6 %. These were determined with the NIR sensor of the forage harvester and for control in the DLG laboratory. The growth heights varied in the trial from 2.90 m to 3.70 m.

Results under practical conditions

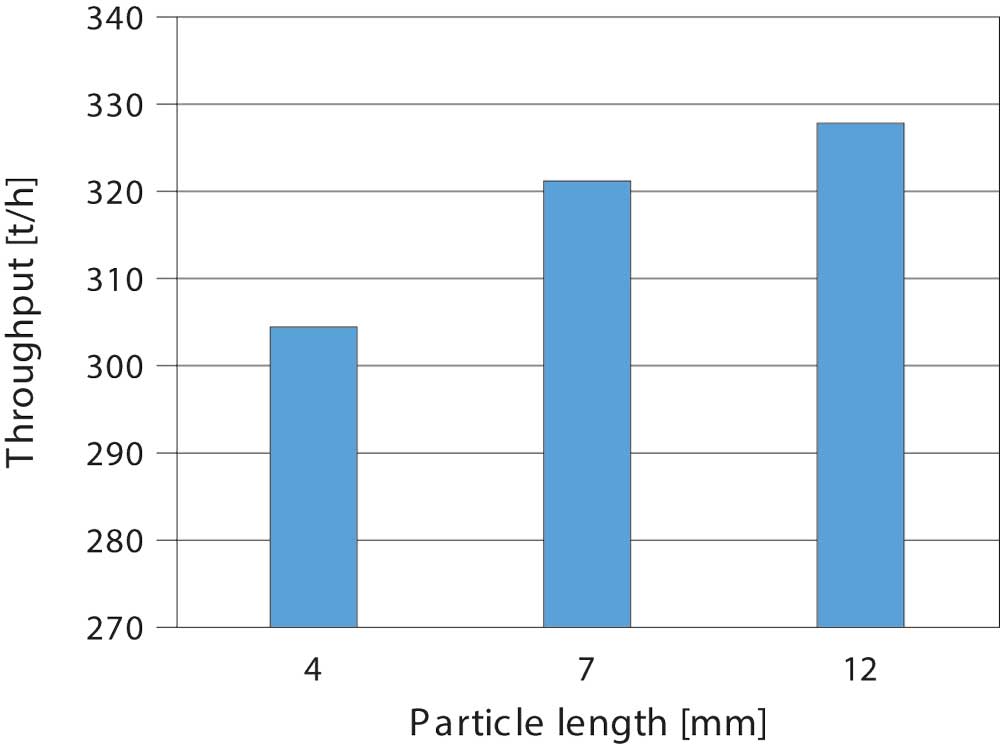

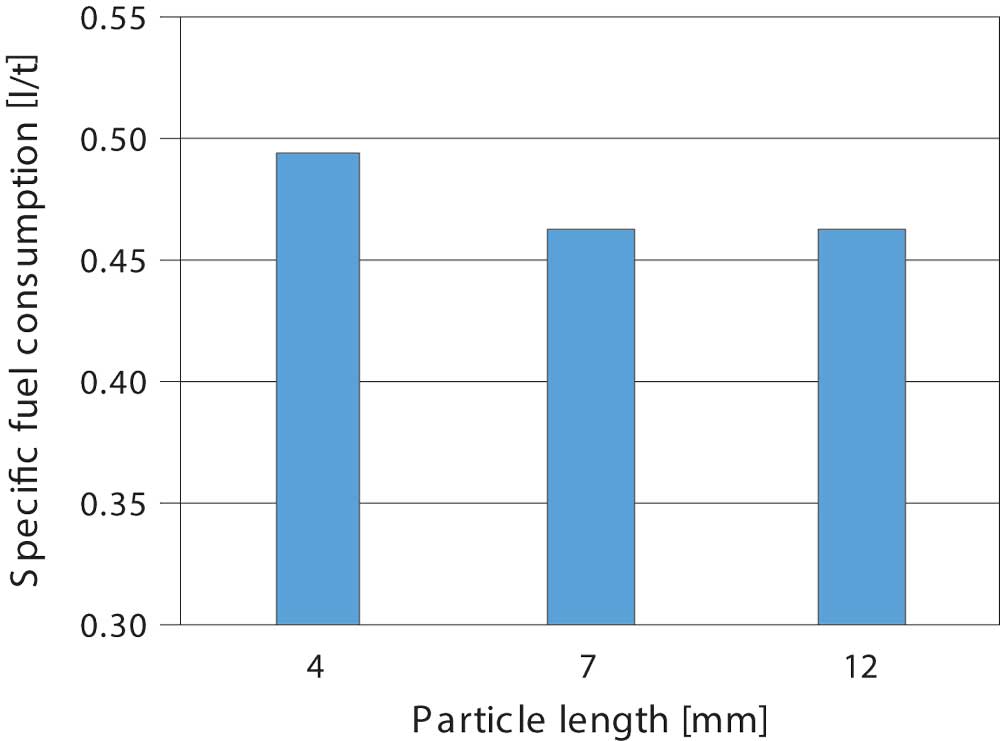

Under the harvesting conditions on site, high throughputs of up to 328 t/h were achieved at a theoretical chop length of 12 mm - with a low specific consumption of around 0.45 l diesel per tonne of crop. The graphs give an overview of throughput rates and specific consumption at different chop lengths.

With a preselected theoretical chop length of 4 mm, almost 60 % by weight is found in the two screen fractions > 3 mm and > 5 mm. This result shifts in the desired direction with longer preselected chop lengths. Comparatively high weight fractions were found for the fines (< 3 mm) in both dry matter content layers. The reason for this could have been that the stands were frozen before the test runs, which can lead to an increased tendency to crumble. Across all chop length presettings, very good and good grain preparation levels were achieved compared to literature data.

Conclusion

The tested forage harvester JD 9800 achieved comparatively high throughputs in the DLG test. It demonstrated its high performance potential under the test conditions and was able to convince with its low specific fuel consumption. Further detailed results can be found in the test report on

https://pruefberichte.dlg.org/filestorage/6891_e.pdf

It is available free of charge on the DLG website.