Slurry separation succeeds

By Susanne Gäckler, DLG Test Center Technology and Farm Inputs

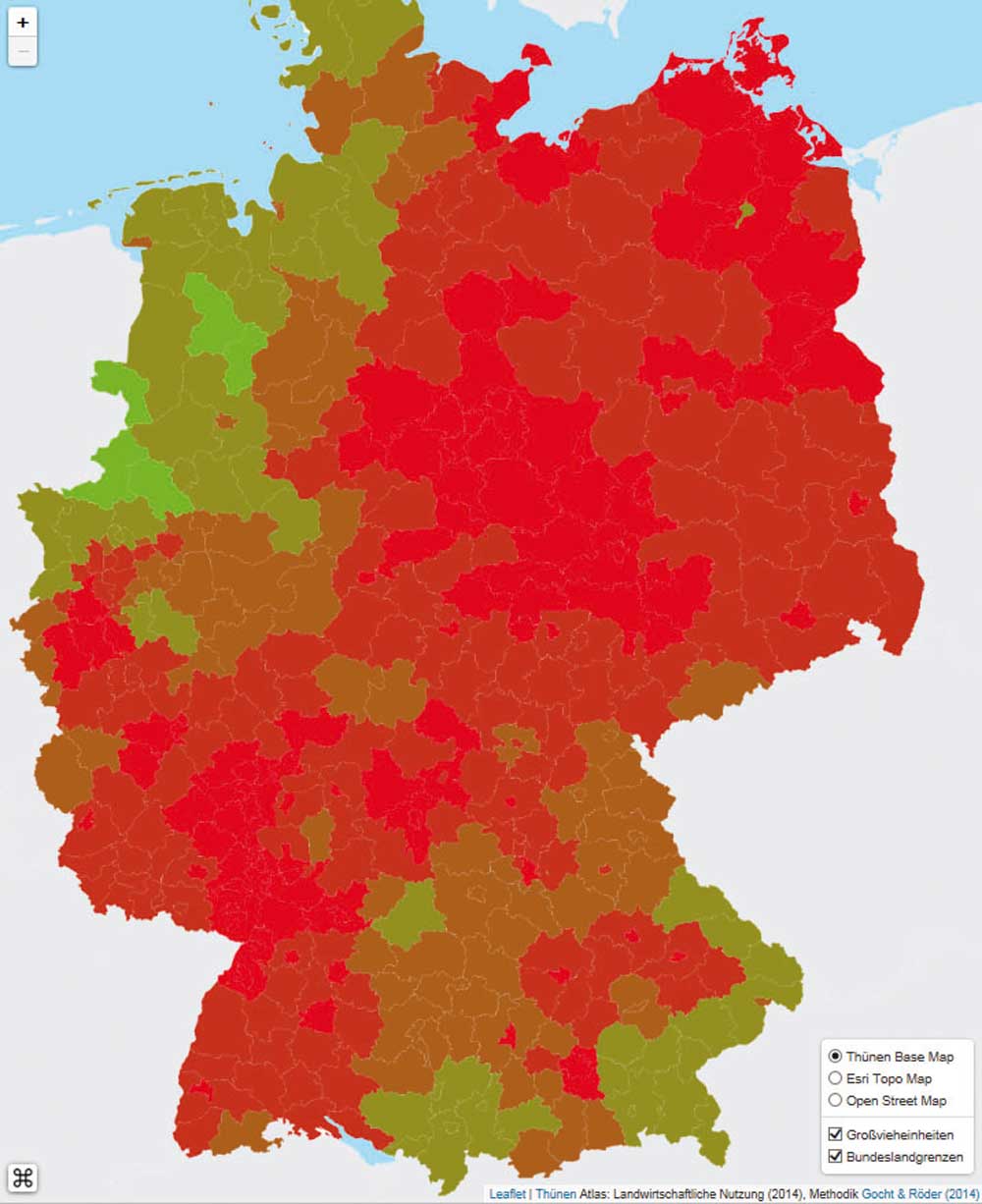

Livestock production is very unevenly distributed across Germany. And we can expect even more concentration of farm animal production under ongoing structural change with successful businesses expanding and less successful farms possibly giving up livestock. On the other hand, farmers face continual reduction in manure application periods and the amounts allowed to be applied per hectare. As a result, a real problem is faced by more and more farmers in regions with high livestock density and the surplus organic manure output that goes hand-in-hand with this. They must either increase slurry storage capacity to bridge the gaps between permitted application periods, or else organise transport of the manure to regions with not enough slurry available where it can supply nutrients to growing crops. But even when used as manure on the farm of production, the increasing size of units means ever greater distances have to be covered from animal housing and slurry stores to outlying pastures and cropland.

The water has to go

In effect, slurry is mostly water. It’s transport therefore rarely pays. Depending on source, raw slurry has a dry matter (DM) content of between 3 and 10 %. To reduce the respective truck transport costs as much as possible, a DM of 25 % or more is desirable, a concentration achievable through separation of slurry liquid and solids.

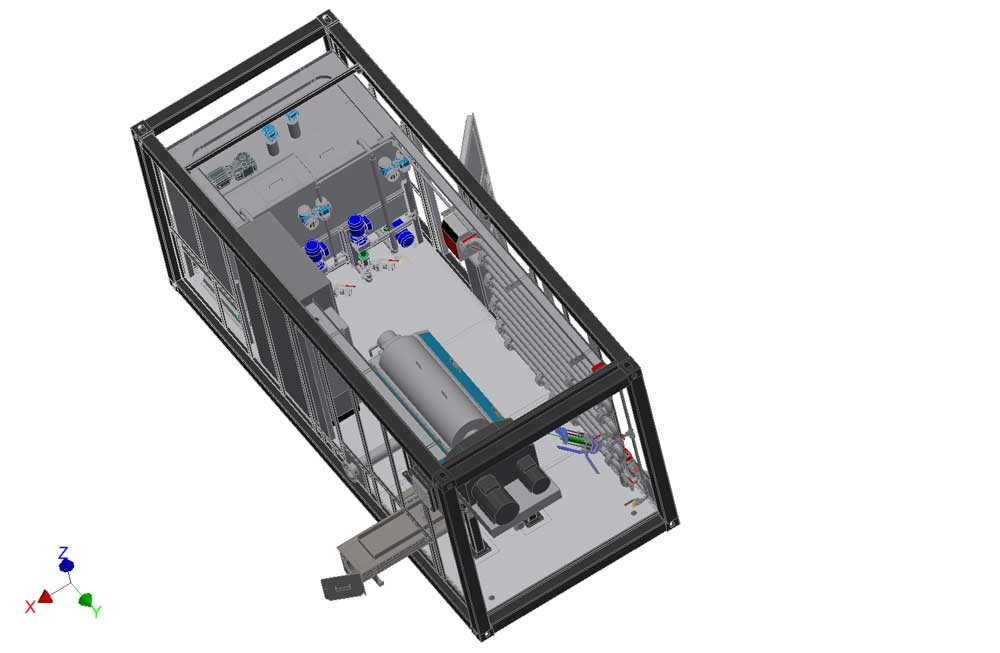

The tested MoRoPlant 20 separation system from Aqua Vivendi carries out this task in two phases. The initial raw slurry is pumped in continuous flow through a 28 m long intake pipe by grinder pump. Thereby two additives are metered into the liquid flow via proportional injectors located in the fourth quarter of the pipe. In the first place, these cause precipitation or flocculation of the slurry. The slurry then flows from the inlet pipe into a decanter centrifuge where solids are separated out. The MoRoPlant system fits as self-contained system within a 6 m long container suitable for transport on a truck or on a trailer chassis. The first additive is bentonite, a clay/mineral material that acts as natural separating agent. The second is a mix based on vegetable starch. The latter aids adhesion of slurry solids to the bentonite and thus creates water-insoluble flocculate which improves the mechanical separation process in the decanter centrifuge and increases degree of selectivity. Additionally, the starch mix breaks down nitrogen compounds improving, among other things, efficiency of N separation.

Intensive recording

Six separate trials were conducted involving slurry from three different feeding pig units and the same number of dairy farms. All tests were conducted on a single site, a large feeding pig unit in Bavaria. Two slurry tankers were loaded at each participating farm, one fitted with a recirculation system for homogenising the slurry within the tank. From this tanker the homogenised material was unloaded into the separation system via grinder pump, the contents of the second slurry tanker being intermittently unloaded into the other via mobile pump, ensuring a continuous supply of homogenised slurry. Hereby, all material flows were recorded with samples withdrawn hourly from all the system inlet and outlet points. The samples from one recording day, in other words from one farm’s slurry, were mixed together with three portions of this mix prepared, one each sent to two contracted laboratories for analysis and another kept as reserve. In the laboratories, the samples were tested for DM content, organic DM, total N and ammonia N, total phosphorus (as P205), total potassium (K20), copper and zinc as well as pH level and C/N ratio. From the results were calculated respective separation efficiencies.

Results and conclusion

Separation efficiency for dry matter lay at over 80 %, for N at over 40 % with feeding pig slurry and over 60 % with dairy cow slurry. A particularly high separation efficiency of over 90 % was achieved for phosphorus. For potassium, separation efficiency was average for feeding pig slurry, although the result for dairy cow slurry in this respect was very good at over 40 %.

In that the definitive DM content of the centrate , i.e. the liquid phase post-separation, always lay under 2 %, the result meets the requirements in article 6, paragraph 10 of the German Fertiliser Ordinance, 2017 where it states: »That the responsible local authorities can permit requested exceptions to the ban on manure spreading during the non-application periods (Par. 8 or 9) where fertiliser DM is less than 2 % and no resultant damage to water body quality is to be expected, and not more than 30 kg/ha total N is applied during the permitted period«.

The detailed results may be accessed free of charge on the DLG website in Test Report 6929 on www.dlg.org/en/agriculture/tests-agriculture/test-reports/on-farm-operations/test-moroplant-20-slurry-separator/.