Special sensory analysis of edible ices

DLG Expert report 03-2011

1. Introduction

Edible ice is a food in which the focus of consumption is on enjoyment. The product group Edible Ices is one of the still young product groups in our food programme. Iced, sweet milk and fruit preparations reportedly existed already in ancient times.

However, it was only the invention of technical refrigeration by Carl von Linde in the year 1876 that created the condition for developing products that require production temperatures well below freezing point. With the availability of coldness in any place at any time, the foundation for making such products and offering them to consumers worldwide was created. Industrial production was possible.

2. Legal bases

In Germany the commercial designations for edible ice varieties, minimum requirements for their composition and the authorised ingredients were specified by law in the Food Regulation of 1933. Since 1998, in adaptation to EU law, the use of all ingredients generally allowed for foods is also authorised for edible ices. The Edible Ice Regulation was thus abolished. However, its content was essentially fed into the guidelines for edible ices in the German Food Code, which describe the prevailing German understanding on the basis of expert opinion as follows:

• Definition

“Edible ice is a preparation brought into a firm or pasty condition, e.g. soft ice, through a freezing process during production, which is brought into circulation by way of trade in frozen condition and is intended for consumption in this condition, in its thawed condition, edible ice loses its shape and changes its previous structure.

• Characteristic ingredients

“Edible ices are produced in particular with the use of milk, dairy products, dairy cream, egg, sugar, honey, water, fruits, butter, vegetable fats, flavours and/or colouring foodstuffs. Depending on the respective edible ice variety and taste, other ingredients are used as well.”

• Combination products

“Edible ice is also brought into circulation in combination with other foods, e.g. fruit sauces, coatings, spirits and waffles and in various product formats such as wafers, cones or ice-cream cake.”

• Edible ice varieties with requirements

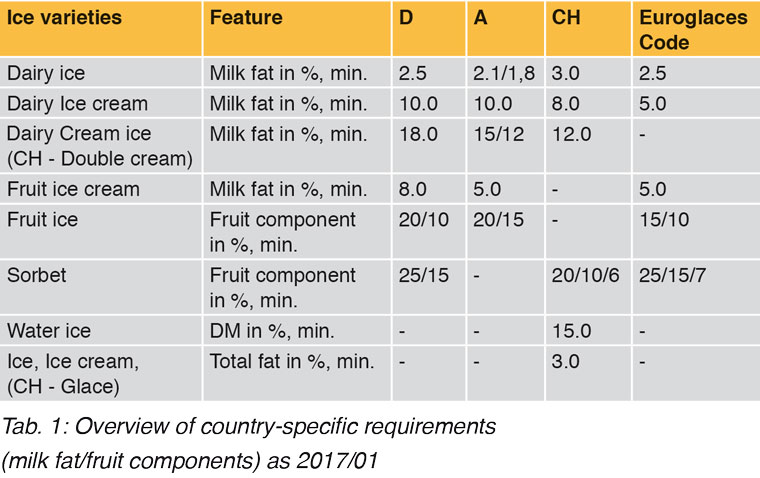

made of the composition The requirements made of the composition of edible ice products are country-specific and are thus not uniform within Europe.

Alongside the German food code, there is for example the Codex Alimentarius Austriacus in Austria and the Ordinance of the FDHA on sugar types, sweet foods and cocoa products (Chapter 5 Edible ices) in Switzerland, which make different requirements with the same commercial names. In parallel the European Ice Cream Association Euroglaces (members are currently 15 European edible ices industry associations) presented a Code for Edible Ices as a harmonisation proposal in 1996. As long as the countries do not take this over in their country-specific requirements, this EU Code is of little importance. Table 1 shows an overview of the requirements.

The fat content and/or the fruit content affect the sensory evaluation result (taste, consistency). Valid comparison tests therefore require products of the same edible ice varieties. Alongside fat and fruit components, the dry substance is a further important parameter for the sensory characteristics. It is partly described in the variety requirements. Nevertheless of outstanding importance for the texture/consistency of edible ices, is the nature and quantity of the sugars used and the incorporation of air (overrun). The latter can lie between 40% and 150% e.g. for ice cream. Products with higher air incorporation are distinctly creamier, but tend towards a foamy, airy texture. Products with less air incorporation have a distinctly more compact and firmer structure, are more difficult to portion and are less creamy.

3. Quality criteria of consumers

In recent years a series of consumer surveys have been conducted resulting in a clear quality requirement made by consumers. According to this, in edible ice products consumers look for high creaminess and good (not artificial) taste. Often a reduced sweetness and/or reduced fat content are desired. In products for bulk consumers, easy portionability is important. Fruity ice varieties are less popular in Northern Europe. Instead the “warm” varieties (vanilla, chocolate, stracciatella) are preferred. In Southern Europe fruity “cold” ice varieties are preferred by consumers.

4. Technology, production process

Alongside the formulation and the selection of ingredients, the production technology exerts a crucial influence on the sensory result of an edible ice product.

Pasteurisation is usual for reducing germs. It can lead to a Maillard reaction due to the heat effect on protein and sugar substances. This leads to the undesired, so-called cooked taste that is assessed as a sensory fault. In production there is a very fine line for the edible ices chef/machine operator between avoiding a cooked taste and achieving suffi cient germ reduction.

Freezing is the actual process step in which the fl uid ice mixture becomes a pasty mass under the infl uence of cold and air incorporation and this gives the creamy ice varieties their typical consistency. The creaminess is infl uenced by the degree of fi neness of the air distribution and by the initial freezer temperature. As a rule of thumb, the lower the temperature, the more stable the ice.

Filling/shaping

The filling temperature depends on the filling technology. Three methods are chiefly used:

a) Extruder filling: in the case of extruder technology a filling temperature of -6 to -10 °C is necessary in order to achieve a suffi cient form-stable plasticity. The ice mass is shaped into a line and then cut into portions or applied as decoration, e.g. dabbed on. Typical products are ice-cream cakes, ice in tubs, ice on a stick.

b) Round table fi lling: in round freezer fi lling the mixture is only frozen slightly (is almost liquid), so that it can spread in the moulds under normal gravity. The pre-frozen mixture is then frozen in the mould. Ice products produced in this way are less creamy than extruded products as the high fi lling temperature (0 to -2 °C) means that the fi ne air inclusions are not retained completely up to setting. Typical round freezer products are ice on a stick products.

c) Valve filling: valve filling belongs between the fi rst two filling technologies described above. The generally very creamy ice is shaped using a mainly star-shaped valve in a single work step together with sauces to form a dab. The sauces are co-dosed either from the side or as a sauce cross in the ice. The fi lling temperature is approx. -3 to -5 °C. Dabs are normally frozen in the form of ice in a tub, decoration or cones.

5. Sensory testing

5.1 General

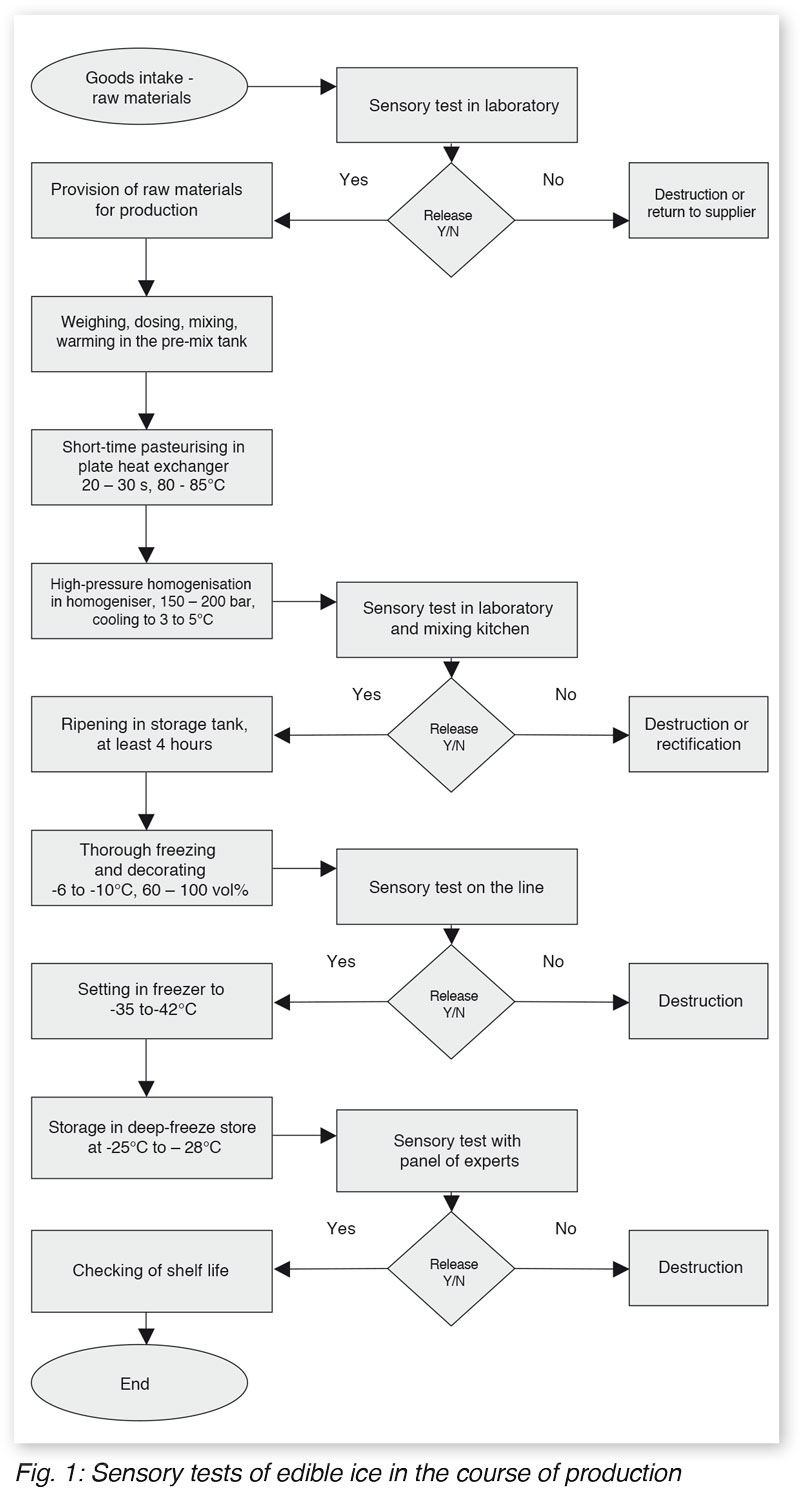

Sensory testing is a holistic testing method that quickly and comprehensively provides information about the properties and attributes of products that the customer/consumer can perceive in the same way. In the production process it is an indispensable and comprehensive testing method to ensure desired product quality and avoid failed batches. Its sphere of use ranges from product development, through product specification, securing of the raw material and production process, to storage and shelf life tests (see Fig. 1).

5.2 Sample selection

The receptor-related homogeneity of edible ice batches is very high due to the production method. Fluctuations within the batch are not expected. This circumstance distinctly limits the number and selection of samples, but regrettably only relates to the basic edible ices mixture. Mixing with sauces, fruit preparations, particulate ingredients such as pieces of nut, garnishings and coatings involves risks of faults which must be taken into account when drawing samples.

5.3 Sample preparation

Edible ices should always be tested at the same temperature (e.g. -18 °C). Only then is a proper comparative test possible and in routine tastings in the production process this is generally based on the “inner standard” of the testers. Edible ice products make high demands of the tester and the organisation of tests. The product temperature is problematic, as it rises very quickly at room temperature and at the same time sensory features change.

As a rule of thumb, the warmer the product, the more intensive the taste impressions are (including the attributes perceived retronasally. Conversely, this means that at lower temperatures impressions are perceptible in weaker form. This applies in particular to the fine, nuanced flavours such as e.g. Bourbon Vanilla, but also to perception of sweetness.

The same holds true for the texture, which becomes softer and creamier as the tasting temperature rises. When planning and conducting edible ice tastings, strict temperature specifications must therefore be ensured for the products to be tested when these are handed out. A nearby cooling unit that can be tempered precisely is an important prerequisite for proper sensory testing of edible ices. The storage period of the items to be tested in the cooling unit must be arranged in such a way that any possible temperature differences are balanced out (e.g. different production temperatures, long transport routes, different post-production storage periods).

As every handling operation, e.g. portioning, can influence the delicate structure and hence the sensory result, the products to be tested should be prepared for tasting without processing and in the packaging. The presentation crockery should be pre-cooled in order to delay the thawing effect as long as possible.

It is advisable to use white china crockery in uniform form and size. Furthermore, documents or IT programs are to be prepared in which the features that are characteristic of the product (taken from the specification) are listed (special creaminess, appearance, colour interplay, desired flavour notes), and for all events standard samples from accepted, preceding production are to be consulted.

5.4 Sample neutralisation/coding

Apart from tastings within the context of product development and comparison tests, coding of the samples offered for quality control is not necessary. Generally each tester knows that the test samples originate from daily production.

5.5 Sample presentation and tasting

The samples are presented to the testers in their original packaging on a pre-cooled white china plate. The workplace is illuminated with dazzle-free daylight lamps (several light sources) in a uniform, shadow-free manner and allows undisturbed sensory testing that cannot be influenced. Optical separation from tester colleagues at the sides and the front is desirable. It should be possible to discuss individual results afterwards and come to a binding end result (consensus). The sensory testing of an edible ice product makes high demands on the senses of the taster due to the low product temperature. Edible ices are able to physically restrict the taste perception (cold numbs!) and thus falsify the sensory result. The quantity offered for tasting, the number of tests and the breaks between tests are to be coordinated with this in mind.

It should be noted that the tasters quickly reach their sensory limits in the case of ice varieties with fat (milk ices, ice cream or cream ice). This is made even more difficult by the fact that the fat is present in the edible ices in homogenised, emulsified and stabilised form and obstinately coats the oral cavity. The obligatory neutralisation between tastings must be carried out carefully. Unsalted white bread and water should be used for this.

In the case of tastings of different ice varieties, the sequence to be followed should be noted. This is fruity ice varieties including water ices without fat before fruity ice varieties with a fat component, ice with a low fat component before ice with a higher fat component. Given the fast warming during tasting at room temperature and the associated change in the attributes of the edible ices, tightly limited testing time is expedient. Furthermore, the testers should wait for their samples, not vice versa.

5.6 Test methods used

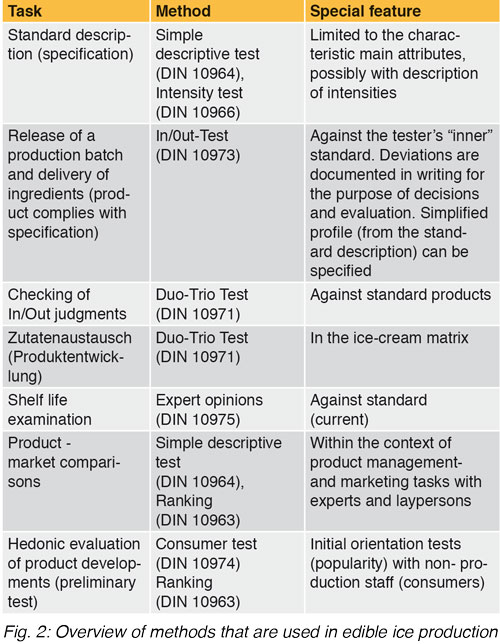

Figure 2 gives an overview of the sensory testing methods usually applied in edible ice production.

The outstanding requirement made of the sensory testing method in a production plant is fast delivery of a result. Consequently the method most frequently applied is the “IN&OUT Test”.

5.7 Testers/panel of testers

5.7.1 Selection and requirement

The diversity of ingredients and their extensive sensory attributes as well as the complex technical influences of the production method require a high degree of expertise and experience on the part of the testers. Generally fast decisions are necessary in order not to impair the progress of the production process.

This results in the following requirement profile for testers:

• good commodity knowledge and basic expertise

• experience in food production

• appropriate sensory faculties

• interest in foods and their sensory testing

• prompt availability

• flexibility (assignments are often irregular and cannot be planned)

• reliability

• good powers of expression

• sound judgement

The first five requirements are generally satisfied by staff in the production, product development and quality assurance departments, so that testers are recruited from these departments.

The most frequent assignments for sensory tests arise in the field of quality assurance. Intake checks of ingredients, process monitoring, final controls and storage tests are the most frequent tasks that are addressed with food sensory analysis methods.

Either the staff of the sensory analysis laboratory or, in medium-sized firms, the in-house laboratory are responsible for selecting and training the panel and preparing the tests. Basically generally known tests such as “identifying the basic taste types”, “threshold levels”, “triangle test”, “simple descriptive test” and “IN&OUT Test” are used for training. A well-functioning sensory monitoring system presupposes knowledge of the specific vocabulary for edible ice products and product knowledge. In order to ensure this, the sensory analysts are regularly informed about the new products and raw materials and coached in their special attributes. This “on the job” training allows fast and reliable results. For this, close cooperation with the product development department that passes on the new products and raw materials to the (sensory analysis) laboratory in the form of samples and information is necessary.

5.7.2 Monitoring of results, basis for training

The sensory performance of an individual tester is the sum of this tester’s experience, product knowledge, sensory skills, powers of concentration and motivation. Weaknesses only become visible in the case of clear circumstances, generally with negative effects. The responsible sensory analyst should regularly compare the individual results with the consensus results in order to identify weaknesses as well as strengths at an early stage. This makes it possible to staff particular assignments correctly and to conduct training sessions in a more targeted manner.

In order to achieve better foundations, it is advisable to include manipulated samples or samples from failed batches from the past on an irregular basis. The responsible officer should announce this approach as an option, but without stating the product, fault or even the time.

5.7.3 Motivation of the testers

The testers have a high level of responsibility, which should be highlighted as such. Regular training for this group not only helps to expand their knowledge, but also their status and standing among the staff. Public documentation of the group result highlights this outstanding activity.

6. Process controls

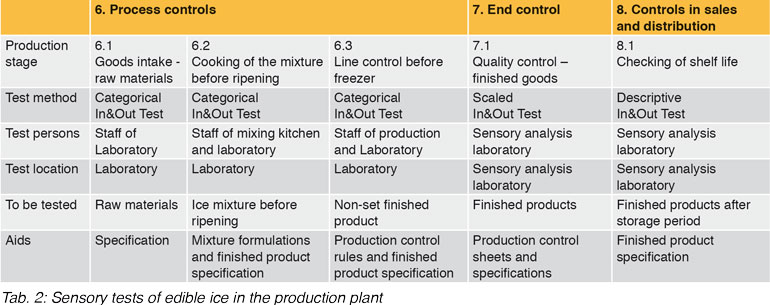

Table 2 provides an overview of the sensory tests in a production plant for ice products. Sensory process controls are conducted flanking production. The aim is to discover any faults occurring as early as possible so that they do not impair further production. The tests are conducted by a group of testers, generally consisting of at least four testers including a head of department or general manager. Each tester first tests individually on his or her own, and the individual results are subsequently discussed and consensus is reached on the binding final result.

6.1 Goods intake – raw materials

The warehouse personnel accept the raw materials on delivery, check the documentation and take the goods into storage. At the same time, a sample is drawn and passed over to the laboratory for inspection according to the test schedule. Also in accordance with the test schedule the raw materials are assessed with the aid of the categorical “IN&OUT Test”. This is a test in which the samples presented are rated either as “IN” if they lie within the sensory specifications, or as “OUT” if they do not comply with these specifications.

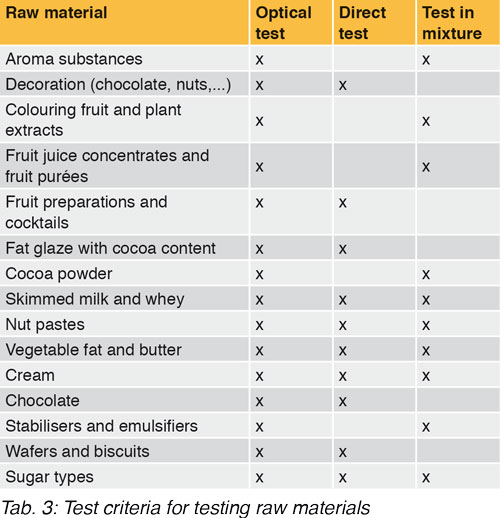

The tests are conducted in the laboratory by laboratory staff who have been given sensory training and demonstrably possess an “inner company standard”. The respective raw material specification with a sensory description of the relevant attributes serves as an aid. All raw materials delivered are inspected in this way.

Table 3 provides information about the test criteria for the most important raw materials. Generally all raw materials are examined optically in a first step. Here gross faults such as deviating colouring, contamination, transport defects etc. can be identified. If the optical test does not produce any findings, either the raw materials are tasted directly in the condition in which they have been delivered, or if this is not possible then in an appropriate matrix. As far as possible the raw materials are tasted in pure and undiluted form (e.g. chocolate in fluid condition). This is always expedient if the relevant raw material is not strongly concentrated and is not provided in an excessively flavour-intensive form. For example, lemon juice concentrate is concentrated so strongly and so intensively sour that tasting in a pure, undiluted condition does not lead to any result. Such raw materials are mixed with a neutral basic mixture in accordance with the specified dose recommendation and tasted in this matrix.

6.2 Cooking of the mixture before ripening

The raw materials of the formulation concerned are weighed out and dosed in the premix tank, warmed and mixed. The mixture is then pasteurised and homogenised. This results in the ice mixture, which is tested in the laboratory by the staff of the mixing kitchen and the laboratory prior to further processing. For this a sample is drawn and tested in cold but unfrozen condition.

It is crucial here that all taste nuances and colour shades are present distinctly more intensively than in the finished product, as the higher temperature and the lack of air incorporation must be taken into account. That is why constant training and careful selection of testers are indispensable here.

The assessment is carried out along the lines of the categorical “IN&OUT Test”, as only a fault-free mixture can be processed. If any faults are ascertained and the mixture is “outside” the finished product specification, either the fault is rectified (e.g. if an insufficient dose of an aroma was added) or the mixture is destroyed.

6.3 Line control before the freezer

The ice mixture which has been released as “IN” by the laboratory then ripens for at least four hours or overnight. This is followed by production of the finished product in the production line with the help of freezer, extruder, fruit mixer, dosing facility, or chocolate coating facility. For all ice creations, air and cold are added to the ice mixture in the freezer along the lines of a scrape chiller for nearly all ice creations. The ice mixture receives the “overrun” as air is worked into it in the form of tiny air bubbles and cooled down to around -10 °C. This then increases the volume to on average 120 vol% and at the same time the mixture becomes creamy. After this the ice mixture is combined with fruit sauces, particulate decoration or coatings and placed in the relevant packaging.

The most important production-flanking check is then carried out by the senior, trained production staff and the laboratory personnel. The finished product that has not yet set completely is tested directly from the production line on the basis of a sampling plan. Here too, the categorical “IN&OUT-Test” has proved to be the most expedient.

The test persons use the production control specifications (including photos) and the finished product specification as aids. They decide with the help of the sensory attributes specified in these whether the product is “IN” or “OUT” of the specification. The prerequisite here is that the products being tested must be standard products that are known and are present as an “inner standard” in the memory of each tester.

If the product is assessed as “OUT”, it is sorted out from the production line directly and destroyed. Products that are rated “IN” are set in the freezer to a core temperature of at least -18 °C, packaged and then stored in the deep freeze store at approx. -25 °C.

7. End control

A final test of the complete production process and the finished product takes place in the end control.

7.1 Quality control of finished product

The next day the entire production of the day is subjected to sensory analysis. The number and quantity of the random samples is specified on the basis of various criteria in a test schedule. The end test is conducted by a panel of experts in the sensory analysis laboratory in the form of a scaled “IN&OUT-Test”. Staff with good product knowledge from all parts of the company (management, production, laboratory, quality assurance, product development, sales and purchasing staff) are trained and selected as testers.

The finished, thoroughly frozen product is tested together with its packaging. The production control sheets and the finished product specification serve as a basis. Generally only slight irregularities occur in this test, as the preceding tests flanking the process rule out distinct faults.

The scaled “IN&OUT-Test” contains a grading scheme in accordance with a 4-point system. Grade 4 means “Well IN”, in other words complete satisfaction of the sensory specification. By contrast, grade 1 means “Well OUT”, in other words not fit for use.

Award of grade 3 “Just IN” allows delivery of the goods, as samples lie within the sensory specification and only slight, unavoidable irregularities have occurred.

However, if grade 4 “Just OUT” is awarded, the expert panel has ascertained distinct faults and the samples are outside the sensory specification. The goods are not delivered and are destroyed. At the same time the causes of this fault must be found and eliminated.

8. Checks in sales and distribution

The control in the sales department aims to check the quality throughout the entire life cycle of a product.

8.1 Examining the shelf life

After successful initial production and delivery of the relevant new product, an examination of the shelf life is started. For this a reserve sample is set aside. This consists of production goods that were assessed as “Well IN”. Within the scope of the test of the shelf life, a sampling plan is specified and sensory tests are conducted in accordance with this. The tests are carried out by the panel of experts in the sensory analysis laboratory with the aid of the descriptive “IN&OUT-Test”, in which a four-grade scale is used as already described for the “IN&OUT-Test”. In addition, attributes that develop in the course of storage are rated with a 9-point scale. For example softening of a cone increases with ageing of the product and can thus be observed. If the shelf life has been reached and the test samples no longer lie within the sensory specification, the shelf life must be shortened or the product optimised.

9. Sensory testing in product development

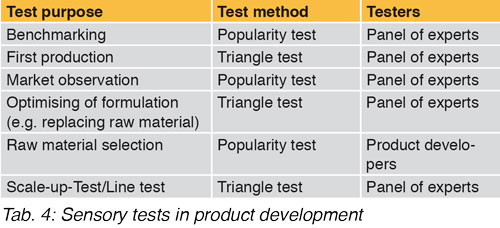

Table 4 provides an overview of the sensory tests in the product development phase.

Within the context of product development a series of sensory tests are carried out. The tests are conducted by staff of the product development department at an early stage and documented as group results.

For example, if a new decoration ingredient such as chocolate pieces is sought, the product development team decides on the basis of popularity on the use of this new raw material. For this a hand sample of the ice recipe concerned is first produced, decorated with the new raw materials entering into question, and assessed along the lines of the popularity test.

After each tester has noted an individual result, the preferences are discussed in the team and the head of the department documents a group consensus. The only aid here is the supplier’s specification.

A similar procedure is adopted for market observation, in which either competitors’ products are subjected to sensory testing by comparison with the company’s own product, or interesting innovations are tested. In both cases pure popularity tests are virtually always conducted. This changes as soon as a competitor’s product is assessed very positively, or if an innovation animates the firm to produce a development of its own. In this case a decision is made to use benchmarking or product optimisation.

Benchmarking means that the competitor’s product assessed as popular represents a kind of benchmark for the firm’s own development. This benchmark is used as a comparison in tasting of the samples produced by the firm itself and its popularity is assessed by way of comparison.

The differences between the competitor’s products and the firm’s own samples are generally so serious that more sensitive sensory test methods would not supply any expedient results. By contrast, optimising of formulations generally initiated by exchanging of raw materials is a different story. The differences occurring are generally very slight and must therefore be examined in detail.

For example, if it becomes necessary to change the supplier of the cocoa powder, the product development department must test this new raw material for suitability. Samples are produced with the new raw material and examined using the triangle test. The testers are then given three samples (e.g. two samples with standard cocoa and one sample with the new cocoa), one of which differs from the others and is to be identified. If this is done successfully, the recipe must be optimised further or a new raw material tested.

The triangle test is also applied for conducting line tests. Samples produced on a laboratory scale that customers have accepted and “purchased” are tested by comparison with products finished on the line. This last test within the context of product development closes the circle of sensory tests in edible ice production. Following a successful line test, the production checks and controls explained above start and flank the new ice creation throughout the entire product lifecycle.

Detailed information on the subject:

- Götz Hildebrandt (Herausgeber): Geschmackswelten.

Grundlagen der Lebensmittelsensorik. DLG Verlag, 2008

- Amtliche Untersuchung von Untersuchungsverfahren nach

§ 64 LFGB (Beuth Verlag)

- Sensory Analysis, Ranking Method: DIN 10963 – Amtliche Sammlung von Untersuchungsverfahren nach

§ 64 LFGB, L00.90-4

- Paired Comparison Test DIN 10954 – Amtliche Sammlung von Untersuchungsverfahren nach § 64 LFGB, L00.90-8

- IN/OUT-Test: DIN 10973, Sensorische Prüfverfahren – Innerhalb/Außerhalb-Prüfung aus dem Jahre 2006

- Leitsätze für Speiseeis, Deutsches Lebensmittelbuch, BMEL

- Code for Edible Ices, Euroglaces

- Codex Alimentarius Austriacus

- Ordinance of the FDHA on sugar types, sweet foods and cocoa products (Chapter 5 Edible ice)