Harvesting crops – Handling properly – Adding values

DLG-compact 01/2019

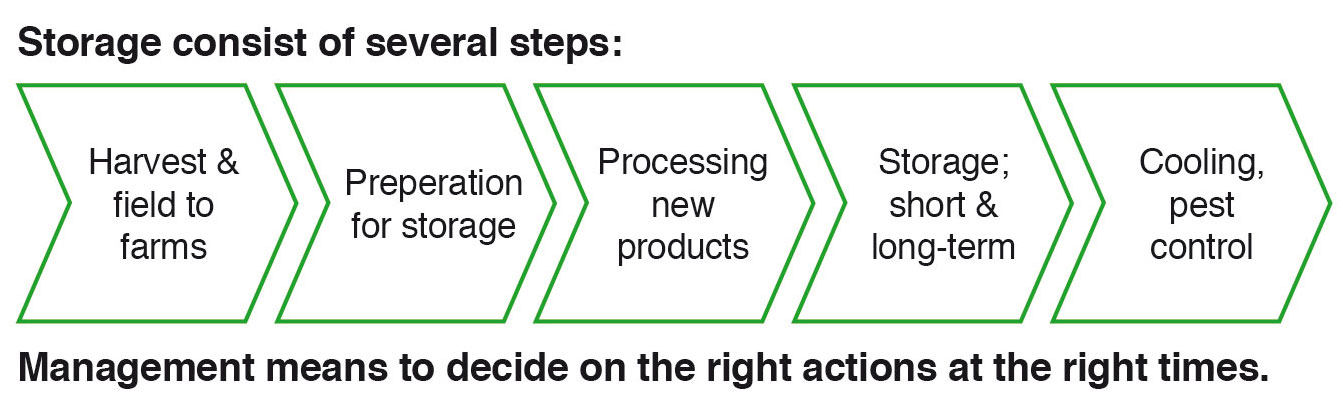

Post-harvest technologies need proper management

Food losses are still a major concern for farmers, wholesalers, merchants, food processors, transporters and consumers. Everybody plays a role, either to prevent food loss or to suffer from it. Indeed, this is not a new phenomenon, and many initiatives have been started towards reducing these losses in order to:

- Increase food quantities for human consumption without using any additional acreage

- Increase food security

- Save disposal costs

- Make farming more profitable and consequently more attractive to young people

- Help create more jobs at various levels (technicians, trade, processing).

Despite all efforts in the past, the problem is still relevant. Some of the reasons for food losses, such as lack of good roads or climate change, go beyond individual responsibilities. However, there is a range of technological options and management tools available to help individuals: every single actor along food value chains can contribute his/her share in reducing food losses.

This document points out some of relevant technical and management measures. In addition, this briefing provides both, examples of how to operate storage systems and a check-list for individual use.

Transportation bins: sizing and cleanliness

Farmers certainly should know best how to harvest crops. The most appropriate transportation bin from the field to the farm gate might be an issue. It is advisable to choose small-sized boxes for perishable foods (example: bins for tomatoes not weighing more than 10 kg). Even if farm-ers are selling the entire yield from one plot of land without grading, transportation in small units does protect the valuabe prod-uct from damage on the way to the farm gate and beyond. Crops with sensitive skin, like potatoes or cassava, should be harvested and transported carefully (not throwing single crops into the transport bin, band-conveyors should ideally be covered with something soft, like rubber). Any partial damage of the skin is potential-ly an entry point for fungal attacks or can accelerate rotting processes. Both are ma-jor reasons for food losses at farm level. Whether farmers are relying on plastic, cardboard, or wooden boxes, it is impor-tant to clean them before use, especially wooden boxes. Furthermore, it is to the best advantage to use any kind of inlay each time when cardboard boxes are used. In some areas, traders provide boxes to the farmers; in this case, clean-ing is even more important to protect the farmers’ produce.

Aflatoxin, Mycotoxin and other fungal attacks are widespread threats in many countries, particularly under warm and humid climate conditions. Management tools and technical options should work hand in hand to cope with this threat successfully! As far as management is concerned, it is important that all actors along value chains take action to protect the produce against fungal infections. As soon as produce is affected at any point, there is a high risk transfering fungi into following stages. Generally speaking, re-ducing the produce´s moisture as quickly as possible makes the difference.

Preparation: sorting ≠ grading

Whether or not farmers are in the position to sell graded produce, sorting out non-storable parts of the yield is a different story. At first sight, it seems to be profitable to keep some little skin-damaged potatoes or some slightly squeezed tomatoes in the box to be sold, but this is a fallacy. The earlier non-storable parts of the yield are sorted out, the better is the quality of the marketed commodity. This will secure the farmers´ reputation as suppliers of high quality products. By the way, those farmers targeting export markets have to fulfill high phyto-sanitation standards anyway. The sorted-out crops are not storable, but may be used as raw material for new products (e.g. dried tomatoes, jam, or fruit juice). This might help families to generate additional income.

Storage hygiene

In general, storage rooms have to be clean. This applies equally for short-term and long-term storage. Particularly after a longer period of storage or when contamination has been detected, disinfection might be necessary. Stored produce should not have contact with the storeroom´s ground soil, first to ensure proper ventilation and second to keep rodents away. The use of tin-collared poles are simple means to detain rodents and thus avoiding contamination with excretions such as feces, urine and saliva. Moreover, preventive measures against birds, bats and cats are to be applied, as well. A generally relevant principle is to store produce in portions, e.g.: potatoes can be filled into stockpiled boxes with max. 800 kg weight instead of having one big mountain of potatoes in a hall. Air can circulate much better in between the boxes, which suppors an evenly controlled climate in the storerooms. For controlled climate conditions to be maintained, keep doors closed. In this regard, it is essential to check temperature and humidity in the storage room on a regular basis as well as sampling produce temperature and moisture.

Furthermore, there are measuring instruments available to check the presence of pests. In case vermin are identified, action is needed. The level of attack defines the measure required (compare principles of integrated pest management), which could vary from removing affected parts of the produce (this is one advantage of storing in portions) to applying agents of chemical or organic treatment. Be aware that in storage systems pests can also evolve resistance to chemical pesticides!

In summary, regular monitoring of storage rooms and the stored produce are essential to identify attacks at an early stage to take the right actions at the right time and using adequate materials; this is what management is all about!

Management checklist:

Management checklist:

| Harvest, field to farms: | Yes | No | |

| Careful harvesting | |||

| Cleaning crops for transportation | |||

| Using clean transportation bins | |||

| Preparation for storage: | |||

| Cleaning storage room (disinfection) | |||

| Identifying rodents´ move-ment paths and eliminating them | |||

| Sorting out non-storable crops | |||

| Processing new products: | |||

| Identifying markets | |||

| Storing additional ingre-dients for processing separately | |||

| Storage short & long-term: | |||

| Regular checking of con-trolled climate and crops | |||

| Maintaining storage facilities after each filling | |||

| Cleaning bins/boxes before refilling | |||

| Cooling, pest control: | |||

| Regular checking of con-trolled climate and crops | |||

| After cooling has been started, safeguarding the cooling chain | |||

| Ensuring that sufficient energy supply for cooling is available | |||

| Reporting of treatment ap-plications for pest control | |||

| General | |||

| Disposing of organic waste to separated locations | |||

| Reporting technical data | |||

| Lessons learnt for next season |