Improvement of Shelf Life of Fruit and Vegetables with Suitable Packaging Technologies

DLG Expert report 7-2018

Download Printversion:

Improvement of Shelf Life of Fruit and Vegetables with Suitable Packaging Technologies

Author:

- Matthias Maisel, Entwicklung Verpackungskonzepte und Analytik (Development of Packaging Concepts and Analytics), MULTIVAC Sepp Haggenmüller SE & Co. KG, matthias.maisel@multivac.de

Contact:

- Simone Schiller, Managing Director of DLG Center for Expertise on Foodstuffs (Fachzentrum Lebensmittel), Frankfurt am Main, Germany S.Schiller@DLG.org

Basic knowledge: Metabolic processes with fruit and vegetables

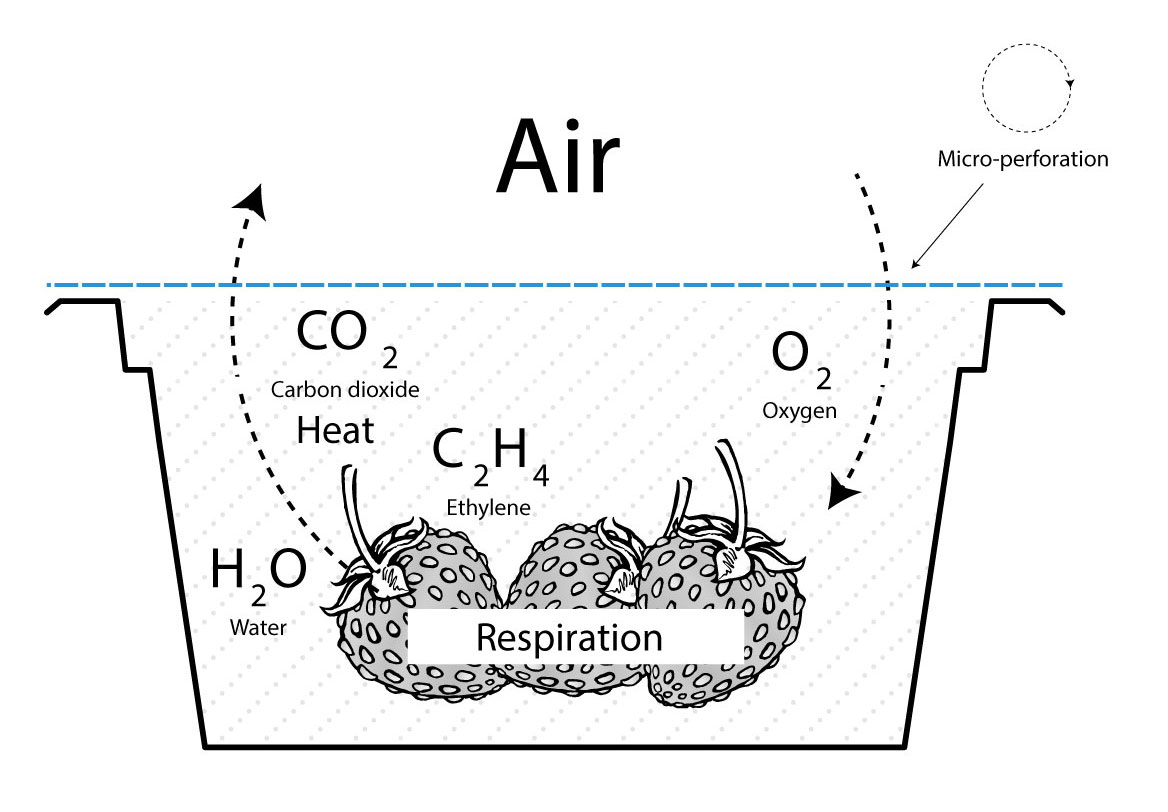

The metabolic process of fresh fruit and vegetables continues even after the harvest, and in the process the vegetable products absorb oxygen and give off carbon dioxide, water and heat. This process is called respiration or breathing. The consequence of this process are ripening, fermentation, discolouration and ultimately definitive spoilage through reduction of the cell tissue and the growth of mould and other undesirable microorganisms.

The ripening gas ethylene accelerates the ripening process and not only represents a special challenge in the handling and packaging process, but also for the consumer at home. It is absorbed by the cells as the gaseous phytohormone ethene and stimulates the ripening of the fruit by causing enzymes to convert storage substances into sugar and energy. This can cause the fruit to become sweeter, but also softer.

Some fruit and vegetables always respire faster, which means the cells age more quickly, and as a result they also spoil more quickly. Others respire more slowly and as a result generally have a longer shelf life. However, the breathing frequencies differ and are dependent on the season and the ambient temperature, location, region or time of harvesting - and the respiration can vary greatly even for the same type.

In general, whole, undamaged products always have a longer shelf life than cut goods. For vegetables and lettuce, and in particular for the trendy ready-to-eat and ready-to-cook mixtures, the danger of microbial spoilage is many times greater, as the protective layer, e.g. a peel, is missing at the cut surfaces. Depending on the type, harvest conditions, degree of ripeness, processing, packaging materials and packaging technology, it is then possible in an extremely short time for discolouration, mould infestation and the collection of liquid to result even before the expiration of the sell-by date, making the product unsellable.

Present and future: Demanding requirements on the market

This means food manufacturers and producers, the industry, packagers, exporters, importers, and the trade are called on to use available, optimum packaging technologies, packaging machines and packaging materials to extend the shelf life and to improve the quality of sensitive, easily perishable products. As a result, they can contribute to improved food safety, maximum consumer protection and the avoidance of food waste.

All participants in the process chain – including the consumers – are responsible for the gentle treatment of resources, the protection of our environment and the containment of food waste, which totals approximately 1.3 billion tonnes per year [1].

With regard to fruit and vegetables, it is even 40 to 55 percent of the cultivated quantity [2], i.e. almost half of all cultivated products that spoil prematurely and are not used.

In summary, today there are mainly four major challenges that have to be met:

- Increasing food safety and consumer protection

- More careful handling of resources

- Development and use of solutions that take current and future trends into account

- Reduction of food waste

Consequently, measures for improved use of fresh, sensitive food have top priority. An important approach for achieving these goals is the packaging process, for, in addition to product protection, packages also contribute to extending the shelf life of package products and increasing food safety. However, it is a matter of utilising technologies that are suitable for the respective food – and which in addition are controllable, need-oriented and also economical.

Packaging technologies are therefore permanently faced with the task of developing need-oriented, modern, holistic solutions for the market which structure the packaging process both safely and economically and achieve optimum packaging results for each product.

Summary

The in-line perforation of standard foils, e.g. with the FreshSAFE concept from MULTIVAC, is an innovative and inexpensive method that contributes to a considerably extended shelf life of sensitive food and – due to the use of standard foils – is also economically viable. This system is suitable for both deep drawing packaging machines and for traysealers.

Established processes: MAP and EMAP

Up until now, MAP and EMAP packages have been used to extend the shelf life of fruit and vegetables. With MAP (Modified Atmosphere Packaging), the natural atmosphere in the sealed package is replaced with a modified atmosphere or gas mixture matched to the respective product. It usually consists of carbon dioxide, nitrogen and oxygen. Their exact composition is based on the type, the storage temperature and the condition of the products, their degree of ripeness, chopping size and other factors. Due to the reduction or adjustment of the oxygen quantity, the breathing activity of the food is reduced and with it the ageing process slowed. If, however, there is a complete absence of oxygen in the package, fermentation begins and the sensory properties of the goods change drastically.

With EMAP (Equilibrium Modified Atmosphere Packaging), in addition to a modified atmosphere, a specific micro-

perforation of the packaging film also takes place that enables an exchange of the atmosphere between the package and the environment. As a result, CO2 flows outward and O2 inward. This enables a balanced atmosphere to be adjusted in the package with which the oxygen enters into the package. In general, a combination of a lower amount of oxygen and a higher amount of CO2 delays the oxidation process, changes in taste and microbial growth. But here as well, both the correct composition of the gas mixture and the perforation must be matched to the product and its natural breathing. In addition, the formation of ethylene must also be taken into account. For the ripening gas can also escape via the micro-perforation, preventing the concentration in the package from increasing too greatly. Only the interaction of breathing and permeability of the foil results in an atmosphere inside the package that extends the shelf life of the food.

The difference between the two methods is that with MAP packages, neither the entry of oxygen into the package nor the exiting of carbon dioxide from the package is possible, while with EMAP an exactly calculated atmospheric exchange adjusted to the product takes place via the micro-perforation.

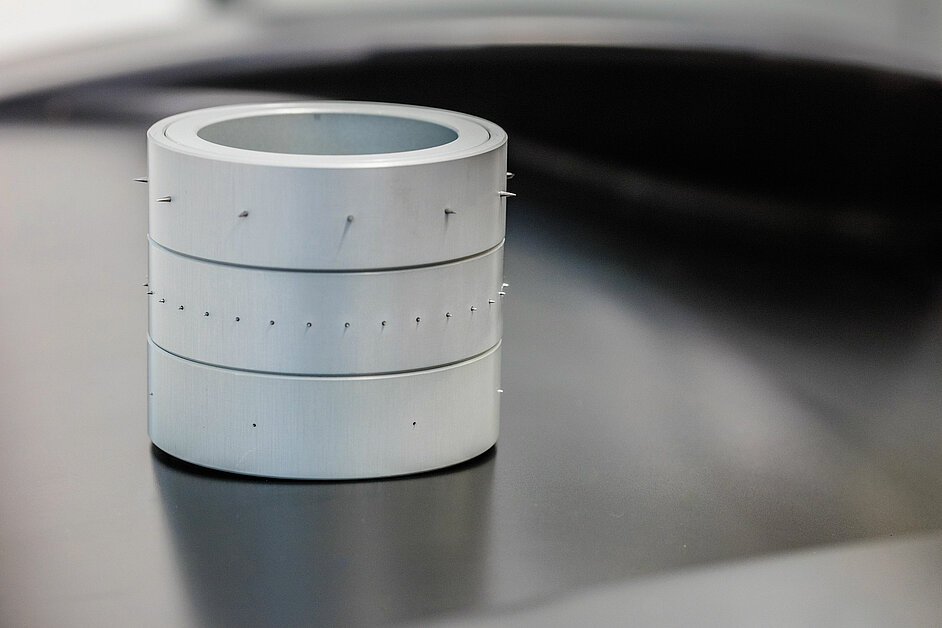

A practical application for the EMAP technology is the innovative FreshSAFE packaging system from MULTIVAC. Here, the foil is perforated when manufacturing both deep drawing packages and tray packages with a perforation station integrated in the machine. This enables standard foils to be processed, eliminating the need to stock perforated foil.

With this system the micro-perforations are produced with proven, quickly interchangeable needle rollers. However, laser technology may also be increasingly used in future. Expensive laser perforation is especially recommended for complex automation solutions.

With inexpensive needle perforation, commonly used upper foils can be adjusted to their individually required permeability. This becomes apparent in the extension of the shelf life, and with it in the reduction of rejects at the point of sale. By using inexpensive standard foils and with sustainable savings for maintenance, a fast return on investment also results and the investment in this kind of system quickly pays off.

Practical examples

Various solutions are available for the differing requirements on the market – in the area of deep-draw packaging machines and for traysealers. Both economic, entry-level models and fully automatic solutions for large batches are available.

A Dutch mushroom producer succeeded, for example, in using the fully automatic MULTIVAC T 800 Tray Sealer to enter into a new market segment. In order to bring fresh and cut mushrooms with the most freshly harvested appearance possible to the wholesale markets and the retail food trade, and then directly to consumers throughout Europe, the company needed a reliable packaging solution that preserves the quality of the sensitive products and enables them to be attractively presented at the point of sale. For this purpose, a package had to be found that takes the development process of the mushrooms after the harvest into account. For mushrooms respire heavily, which is clearly evident in discolorations and the loss of water. The consequence: They lose their freshness, their appetising appearance and, of course, they also lose weight. Consumers then recognize from the

dark-brown to black discolouration of the gills and a shrunken, dry surface whether the mushrooms are still worth buying.

An EMAP package like FreshSAFE from MULTIVAC was really able to convince the customer. In comparison tests the shelf life of the mushrooms packaged with this technology doubled from four to eight or nine days. This then resulted in considerably more flexibility for the delivery chain. And for the mushroom producers the possibility of bringing the cut or whole mushrooms onto the market and therefore directly to the consumer.

In-line perforation with needles can be flexibly adapted to various packaging formats, therefore enabling the permeability of the top foil, the package size, the product, the weight and the storage temperature to be taken into account – and then when using inexpensive standard foil. There is no need for the foil to be changed when changing to a different format or product; solely the needle perforation can simply be expanded or reduced. A major advantage of the sealed tray packages is the trays cannot easily be opened in the supermarket by the consumer for visual and haptic inspection of the package contents prior to purchasing. This also contributes to better product protection, an extended shelf life and reduction of product waste.

Summary

On the whole, high-pressure processing, which is suitable for processing both vacuum packages and packages with a modified atmosphere (MAP), offers several advantages compared to preservation with heat treatment: While vitamins are lost or decomposed through the effects of heat and the heat also usually does not have a uniform influence, with this non-thermal method the vitamins and other sensitive substances are largely preserved, and undesirable micro-organisms are reduced or eliminated. Consumers benefit from high-pressure processing, as fresh and processed foods or ready-made meals in top quality can be stored for longer periods.

Figure 5: Deep drawing packaging machine and tray sealer each with FreshSAFE application

Contact:

Simone Schiller, Managing Director of the DLG Competence Centre Food, Frankfurt am Main, S.Schiller@DLG.org