DLG Expert Knowledge Series 398: Automatic Feeding Systems for Cattle

Technology – Performance – Notes on Planning

1. Introduction

Growing numbers of dairy and beef cattle on farms are leading to higher workloads. In pursuit of the objectives of reducing working time, making it more flexible, facilitating work and caring for their herds on an individual animal basis, growing family farms in particular are increasingly starting to automate work processes. One example of this is Automatic Milking Systems (AMS), which have become ever-more widespread in the last 20 years, especially in regions with medium-sized dairy herds. However, automation of feeding using automatic feeding systems is becoming increasingly popular too. It is estimated that around 1,000 systems are currently in operation throughout Europe (Bonsels et al., 2013). Bavarian farms are investing more strongly in this technology. By the end of 2014 there will probably be more than 100 automatic feeding installations in operation. By contrast, according to manufacturers, only 22 farms in this region were using automatic feeding methods in spring 2011.

As shown by a survey conducted by the Institute of Agricultural Engineering and Animal Husbandry of the Bavarian State Institute for Agriculture in spring 2011 among 21 dairy farmers using automatic feeding systems, the motives leading farmers to invest in an automatic feeding system vary widely. While from the entrepreneurial point of view the majority of the farm managers hope in particular to reduce the physical strain of dispensing the feed, cut down on labour time requirements and make working hours more flexible, another target is to save costs of construction and mechanisation. Alongside these labour management and process engineering aspects, dairy farmers also focus on the benefits for their animals. The majority appreciate the possibility of dispensing freshly produced rations several times a day and hope that as a consequence less feed residue will be left in the trough. By using the option of linking feeding to performance groups, the farmers seek to improve feed conversion of the mixed rations of their cows. About half of the farmers surveyed used automated milking operations in addition to automated feeding. These farms aim to increase herd activity by more frequent feed presentation and consequently to achieve higher and more uniform use of their automatic milking systems in the course of the day (Oberschätzl, 2012; Siefer, 2012).

But what technical options are currently available to meet the farmers’ expectations? And what aspects need to be taken into account when planning an automatic feeding system? This pamphlet addresses these questions in more detail.

2. Automatic feeding systems

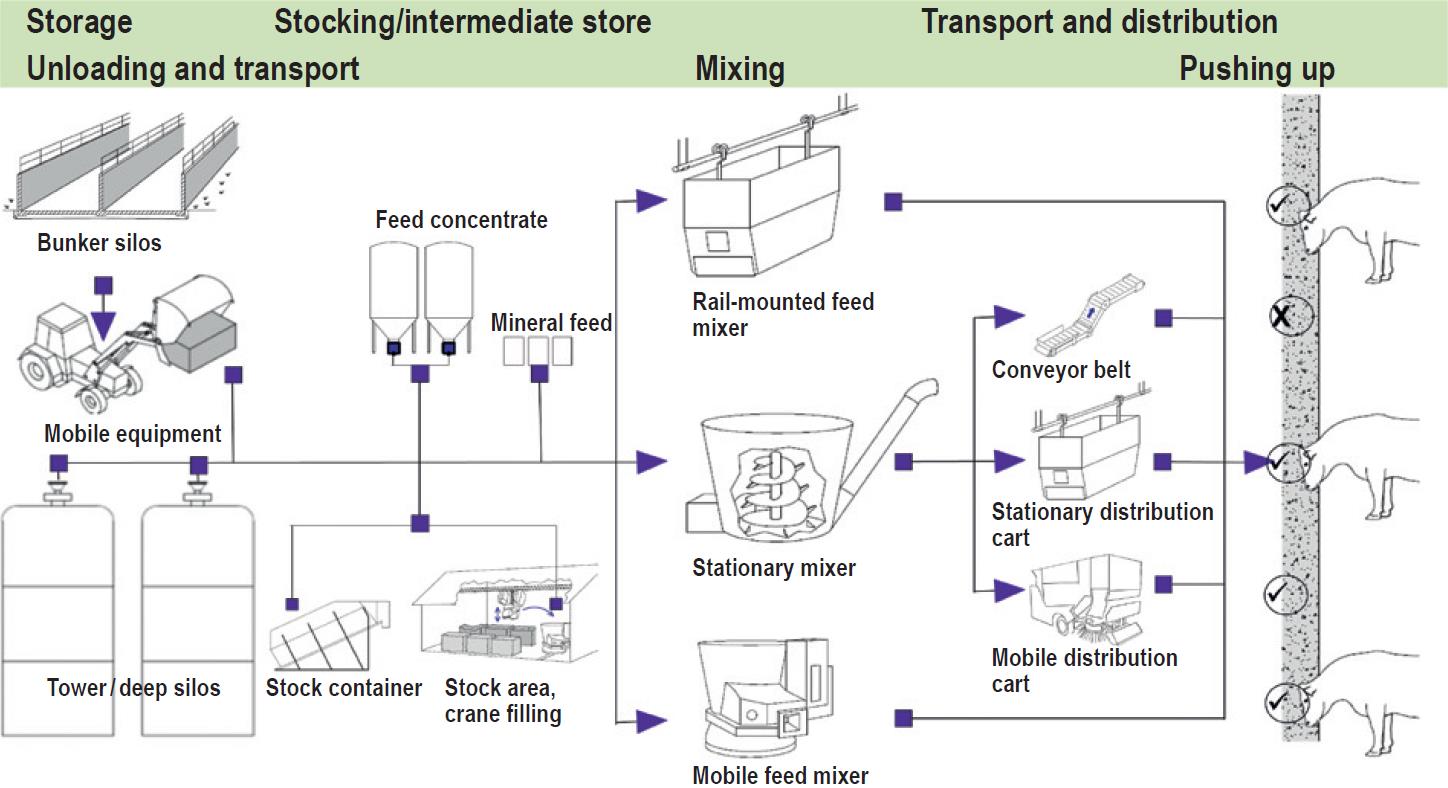

A number of different automatic feeding systems are currently available on the market. These can be combined and used to meet individual farm requirements. It is possible to distinguish between three automation stages (Haidn et al., 2013):

Stage I: Mixing – Distribution – (pushing up)

Stage II: Filling mixer – Mixing – Distribution – (pushing up)

Stage III: Unloading and Transport – Filling mixer – Mixing – Distribution – (pushing up)

In automation stage I a stationary feed mixer has to be filled by mobile equipment from bunker silos. The advantage of this variant is that a performance group can be fed automatically several times a day, but filling the feed mixer still takes up time. Stage II is characterised by being able to feed all performance groups several times a day, while the farmer is no longer tied to fixed filling and feeding times. However, the stock containers represent a major cost factor. Fully automatic feeding in stage III has so far only been carried out in conjunction with tower or deep silos, but these must be classified as comparatively expensive in construction and power consumption. Figure 1 provides an overview of the various techniques in the process chain for realising the different automation stages.

2.1 System overview

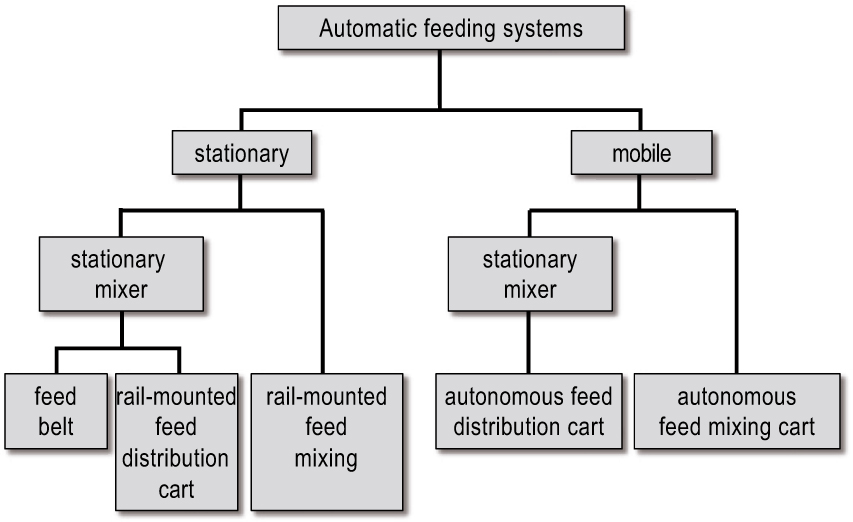

Various technical approaches have been developed for automatic feeding of cattle (Figure 2). While only one prototype in the form of a compound feed demand station (Atlantis system from Lely) was developed for individual animal feeding and not pursued further, only group-related systems are in use today. With this method the same ration is presented to an animal group at its feeding placed several times a day (Wendl & Harms, 2007).

The group-related systems can be sub-divided into stationary and mobile systems. Essential differences between these systems lie in the stocking of the feed and the mixing system, which can be designed in accordance with conventional methods of feed mixer wagons (horizontal, vertical, free fall mixers). Further distinguishing criteria are the delivery of the feed mix (feed belt, rail-mounted distribution and mixing cart, self-propelled feed distribution and feed mixer carts) and the drive system (power towing cable, power rails, battery, internal combustion engine) (Wendl, 2011b).

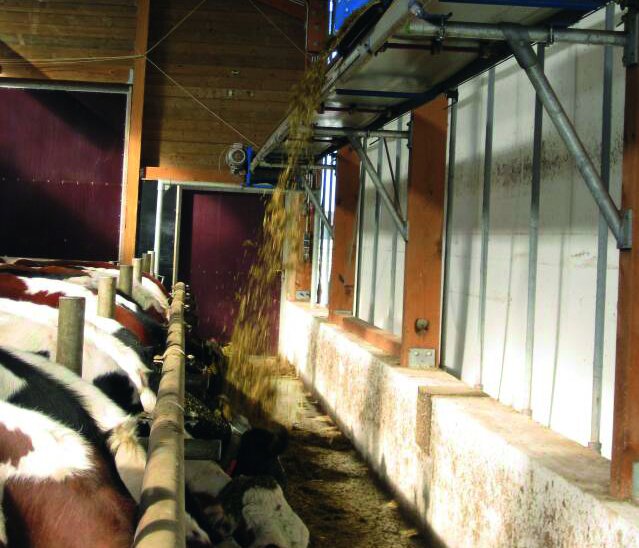

Stationary systems are fixed in position. Here the feed is conveyed further from a stationary mixing container, without the system itself moving to the target location. These systems include the feed belts that were developed in the 1960s and used on larger East German farms (Heber, 2011; Wendl & Harms, 2007). They are mounted over the feed alley. The feed is brought to the feed alley with the help of a conveyor belt and ejected from there by a moving pusher (Figure 3) (Jungbluth et al., 2005). For example, the firms GEA and Pellon offer belt systems. However, feed mixes are also delivered via a rail-mounted distribution cart. While the stationary mixer has to be filled mechanically by the farmer, the maximum possible number of rations is limited by the number of ration mixes (stage I). In practice, 2 to 3 mixes are frequently produced, the last of which is presented to the lactating cows several times a day. However, if the mixer is filled automatically without the presence of an operator being necessary (stage II + III) a number of rations can be mixed and distributed each day. This depends on the capacity of the technical components. The rations dispensed can be performance related.

Stationary systems with a rail-mounted distribution or mixing cart are widespread in practice. They are used particularly in Scandinavian countries (Wendl & Harms, 2007). The rail-mounted system is made up of a distribution cart with or without a mixing function and stock or mixing containers (Figure 4). The area of the cow shed that is to be serviced by the cart must be defined by rails, points and contact positions.. The carts are filled automatically with the individual components from the stock or mixing containers. The ration is then presented to the corresponding animal group.

Depending on the technical resources, the stock or mixing containers can be filled mechanically via tractor-mounted equipment or automatically from tower or deep silo facilities (Grothmann & Nydegger, 2009). Such processes make it possible to produce and distribute several rations a day (stage II). Various manufacturers are intensively engaged in developing these systems further.

The mobile systems represent a special application. It is possible to distinguish between two variants: the mobile self-propelled feed distribution cart with an upstream stationary mixer and the mobile self-propelled feed mixer cart. An example of the former is the Multifeeder V4 of the Cormall-CCC-Robot system. This is a self-propelled feed distribution cart that not only distributes feed, but also automatically unloads the feed mixes from stock containers known as “mixing tables” (Wendl, 2011b). The cart is steered via induction loops in the ground and sensors. According to the manufacturer, this unit can supply up to 800 cows. The Multifeeder V4 is powered via a diesel engine. This variant can also be steered manually by the farmer (Figure 5). The Innovado system from Schuitemaker operates on a similar principle. This method can fill its mixing container automatically at the bunker silo (Heber, 2011; Wendl, 2011a), but is not yet available commercially.

The electronic farm log thus serves for operation monitoring and steering of the waste air cleaning facility for the operator. In the case of deviations from the actual and target values, correction measures are to be undertaken, and where appropriate maintenance and cleaning work are to be carried out in order to ensure continued proper operation.

Nowadays, the electronic farm logs are mainly integrated into the facility control and equipped with touch panels that allow a fast overview of the current operating condition. The memory unit is generally equipped with an SD card shaft, via which the stored data can be read out by authorised persons e. g. in CSV or Excel format. Permit-issuing authorities are increasingly making use of this within the context of their surveillance activities. In conjunction with corresponding maintenance contracts, the facilities can also be monitored online by the manufacturing companies. They provide the operators with tips on appropriate intervention and fault corrections, or the manufacturers carry out this work themselves on site.

The facility monitoring with the aid of the EFL should be used by the operator to optimise operating costs too. The increase in pressure loss across the entire waste air cleaning facility, or for individual stages in the case of multiple-stage facilities, can be read out from the EFL. The pressure increase in trickling bed reactors and multiple-stage methods reacts very sensitively to the degree of soiling of the waste air cleaning facility (WACF). Soiling occurs for instance as a result of dust deposits, in particular as a consequence of incomplete or interrupted sprinkling and due to the clogging of cleaning-active areas with microbially active material. Pressure-stable fans can admittedly compensate such an increase in constant air volume flow for a period, but need increasingly more costly energy to do so. With the help of the EFL, the WACF can thus be run specifically in the range of optimal operating parameters and the cost efficiency of waste air cleaning can thus be improved (see also Chapter 6).

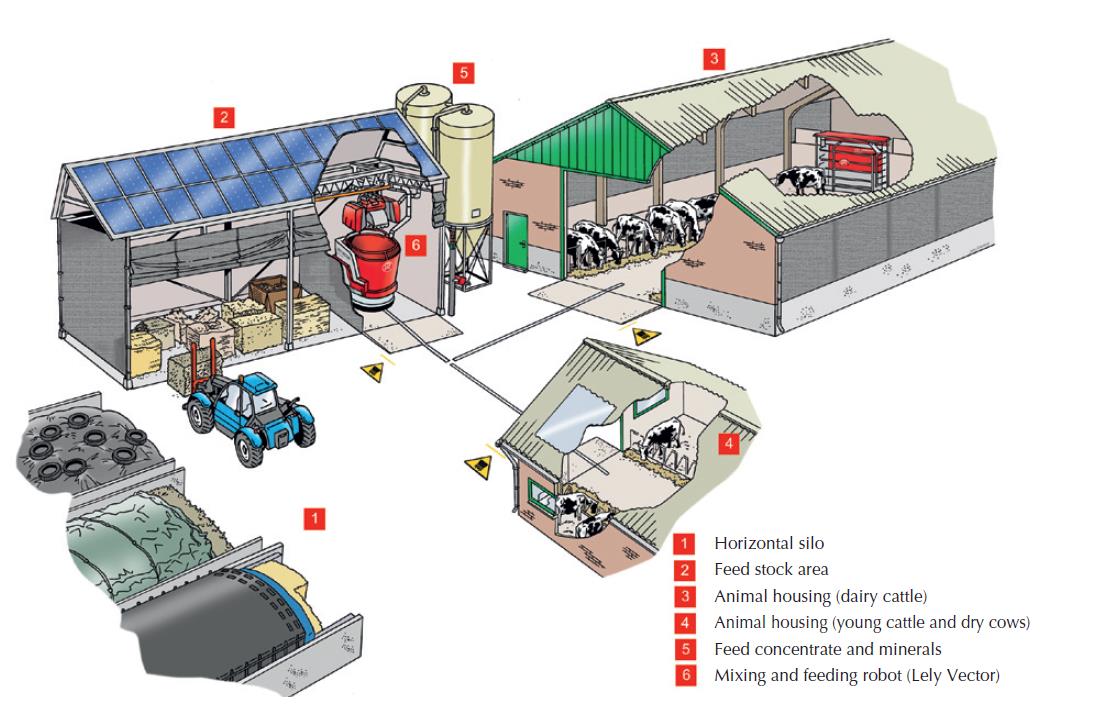

In spring 2012 the manufacturer Lely also presented an autonomous system (Vector). This selfpropelled,battery-operated mixing cart is filled by a grab in the feed store, mixes the components while docked onto the power grid, then proceeds using battery power via metal loops in the ground to the barn. It then scans its way along the feed fence with the aid of ultrasonic sensors and distributes the respective rations there (N. N., 2012). A further special feature of the Lely Vector is its ability to record feed residue quantities at the feed alley via a sensor and add fresh feed in accordance with requirements. In addition this unit also pushes up the feed (Figure 6).

2.2 Machinery and equipment

2.2.1 Links in the process chain

The individual links in the possible process chains of automatic feeding systems in Figure 1 are described in more detail below.

Unloading and transport

The following aspects must be taken into account for swift unloading and smooth transport of the components:

- Unloading equipment with a high capacity (grab buckets, shear buckets, block cutter ➝ equipment mounted at the front or rear of tractor or wheeled loader)

- Short distances from the feed store to the supply and mixing area

- Concreted areas or hard standing

Stocking/Intermediate store

The components can be stored in containers or a covered stock area with unloading by crane. This latter concept is pursued by Lely.Where possible, a separate storage area that can be equipped with three different variants of crane mounting with a grab is recommended for this type of system (fixed rail, overhead crane, gantry crane).

Table 1: Operation and dimensions of the stock containers of various manufacturers of automatic feeding systems

| Features→ | Stock forms | Floor design | Dosing system | Dimensions (m) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Manufacturer ↓ | Blocks | Bales | Loose | Chain | Pusher floor | Open | Closed | Cutting device | Cutter roller | Dosing roller | Length | Width | Height (total) |

| DeLaval | x | x | x | x | x | 4,6 – 9,6 | 2,1 | 3,7 (variable leg supports) | |||||

| GEA/Mullerup | x | x | x | x | x | x | 3,5; 6,0; 9,0 | 3,0 | max. 4,5 | ||||

| Hetwin | x | x | x | x | x | x | x | 6,1; 7,1 | 2,1; 2,4 | 1,8; 2,7 (variable leg supports) | |||

| One2Feed | x | x | x | x | x | ||||||||

| Pellon | x | x | x | x | x | x | 5,1; 7,1; 9,1 | 2,3 | 3,2 – 5,4 | ||||

| Schauer/ Rovibec | x | x | x | x | x | 5,4 | 2,7 | 3,7 | |||||

| Trioliet T30 | x | x | x | x | 6,6 | 3,0 | 3,5 | ||||||

| T40 | x | x | x | x | 6,0; 7,4; 8,7 | 1,96 | 2,5 | ||||||

| Wasserbauer | x | x | x | x | x | x | 6,0 | 2,5 | 2,1 (variable leg supports) | ||||

However, feedstuffs are most frequently stored in stock containers. The equipment varies from manufacturer to manufacturer. Table 1 provides an overview of different variants.

The silages can be stored loose or in bales or blocks in the stock container, depending on the manufacturer. It is recommended that silages be stored in blocks or bales, however, in order to minimise the influence of air and thus any microbial changes. The necessary container sizes for the individual feed components in the ration have to be calculated.

The following formula can help here:

VB = TZ * QuantityK * (1/ρ) * (1/n) * (1/Vnutz) * 100

VB: Volume of stock container (m3)

TZ: Number of animals

QuantityK: Quantity of the component per animal and day (kg/animal/day)

ρ: Density of the component (kg/m3)

n: Stock container filling frequency per day

Vnutz: Volume of the stock container utilised

Table 2 shows the required storage volume for grass and maize silage (unloading with grab bucket) depending on different animal numbers. The grass silage here is forage wagon silage, while the maize silage is chopped silage.

Table 2: Storage volume required in stock containers for grass and maize silage (grab shovel unloading) as a function of different cow numbers

| Components | Storage volume required (m3) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Feed quantity (kg FM/ cow/day) | Density (kg FM/m³) | Useful volume (%) | Filling frequency/day | Number of cows | ||||||

| 50 | 100 | 150 | 200 | 250 | 300 | |||||

| Grass silage | 22 | 350 | 70 | 1 | 4,5 | 9,0 | 13,5 | 18,0 | 22,4 | 26,9 |

| Maize silage | 18 | 400 | 70 | 1 | 3,2 | 6,4 | 9,6 | 12,9 | 16,1 | 19,3 |

Mixing

Depending on the feeding system, the rations can be mixed with the aid of a stationary mixer, a rail-mounted feed mixer or a mobile mixer. These work in accordance with the systems known from feed mixer carts (vertical, horizontal, free-fall). Depending on the equipment of the feeding system, the mixer can be filled with feedstuffs via belts from the stock containers. However, feed residues can accumulate beneath the belts – especially if very fine material is being used such as, for example, lucerne hay – and lead to the conveyor belt stopping. In order to reduce any imprecision of the component dosing in the mixer, the belts can be equipped with a weighing facility, but weaknesses can occur here too.

The selection of the mixing system should be guided by existing components and the components used (important: note the length of straw, hay, grass silage!). Chop lengths of 3 – 4 cm are recommended for good mixing quality of the rations. However, as the forage wagon and bale materials frequently display chop lengths of approx. 15 cm, it is necessary to shorten the components. To meet this demand, additional cutting facilities are necessary at the feeding installation, or else only chopped material should be used. This can help to achieve lower wear of the machinery and equipment. Flexible speed settings can ensure better emptying of the mixing container when discharging the ration, leaving smaller residual quantities. Many systems now possess features for compensating deviations in a feed ingredient quantity in the ration in the next ration produced.

Transport and distribution

The following transport and distribution facilities are used (see Figure 1):

- Conveyor belt

- Stationary distribution cart

- Stationary mixing and distribution cart

- Mobile distribution cart

- Mobile mixing and distribution cart

Depending on the distribution system selected (see Figure 2), different demands are made of feed alley widths (table 3).

Table 3: Requirements of feed alley widths depending on the distribution system

| Distribution system | Recommended feed alley width (m) | |

| one-sided dispensing | two-sided dispensing | |

| Conveyor belt | 1.50 – 2.00 | 2.0 |

| Rail-mounted | 2.0 – 2.5 | 2.5 – 3.0 |

| Mobile | 2.5 – 3.5 | 3.5 – 5.0 |

These are functional dimensions that have proved efficient. Despite this, it should be taken into consideration that if a feeding system fails, it should be possible to drive through the feed alley with a yard loader. Moreover, if feed alleys are too narrow, there is a risk of mixing the different rations of different performance groups that may be standing opposite each other. Some manufacturers offer the option of dispensing on both sides of narrow feed alleys, which is why only one central rail positioned in the middle over the feed alley is necessary, and where appropriate the opposite trough rows can be supplied.

Depending on the distribution facility, a different support structure with the necessary structural requirements is necessary. A rail-mounted mixing and distribution cart, for example, requires a stronger support structure than a pure distribution unit. Furthermore, the rail structure on which the distribution facilities are mounted may be galvanized, among other finishes. However, galvanised parts can be subject to material abrasion. Such shavings should not be able to make their way into the feed. Appropriate rectification measures are to be undertaken.

Table 4: Demands made of the different drive variants of rail-mounted automatic feeding systems with assessment

| Power supply | Drive ratings | Demands made of equipment | Advantages | Disadvantages |

| Current rail | 48 and 400 V | Splash-water protected | Safe power supply; can easily be expanded; gradients can be overcome | More expensive technology (running and power rail); point settings restricted |

| Towing cable | 400 V | Safe energy supply | Travel round bends possible to limited extent; cannot be expanded at will; no point settings | |

| Accumulator battery | 12 V | High performance batteries (charging duration approx. 6 h/day) | Flexible use, simple technology (running rail) | Only slight gradients; long charging times |

2.2.2 Drive systems for mixing and distribution methods

Depending on the farm situation, manufacturers of automatic feeding systems offer different drive systems to suit the power supply. The greatest diversity is found among rail-mounted, automatic feeding systems. However, the drives involve a number of requirements as well as advantages and disadvantages (table 4). Mobile feeding robots can be powered by a diesel engine or a battery-supplied electric motor. Facilities with conveyor belts are also supplied with electricity via electric motors.

2.3 Structural requirements

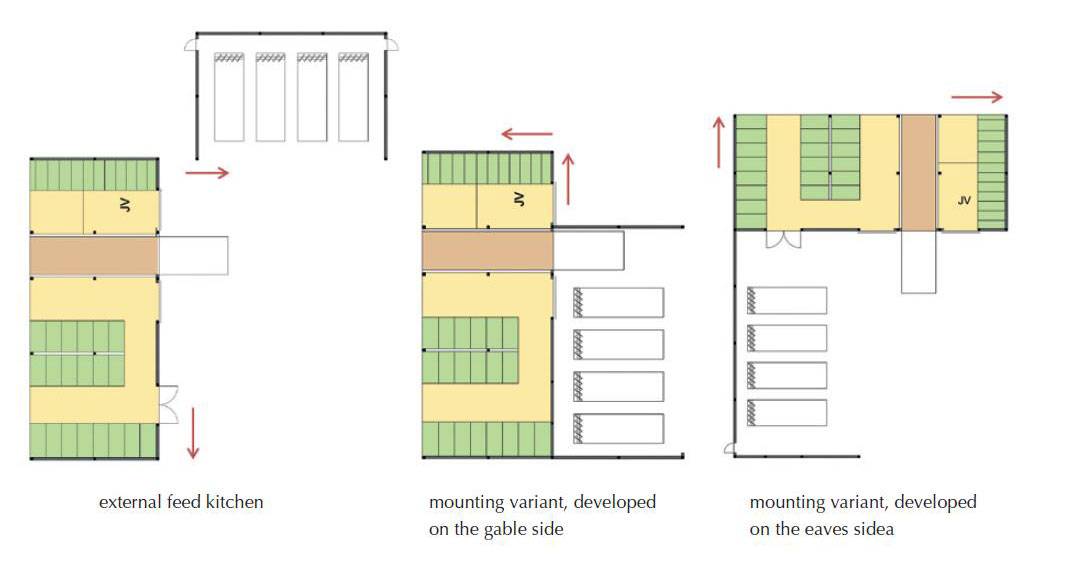

The design of the feed kitchen represents a key factor for successful operation of an automatic feeding system. Depending on the feeding resources and the operational situation, various arrangements of the kitchen beside or in the barn are possible (Figure 8). However, fire protection regulation aspects, options for expanding the animal housing and access to the building as well as connection between feeding and the animal housing should be taken into account.

The following further aspects are to be considered during planning:

Dimensions

- Number of components stored in stock containers and their manufacturer-specific size influence the space requirement (table 1) – a 6 m grid is recommended

- The feeding system resources influence the space requirement (stationary mixer and distribution facility require additional space)

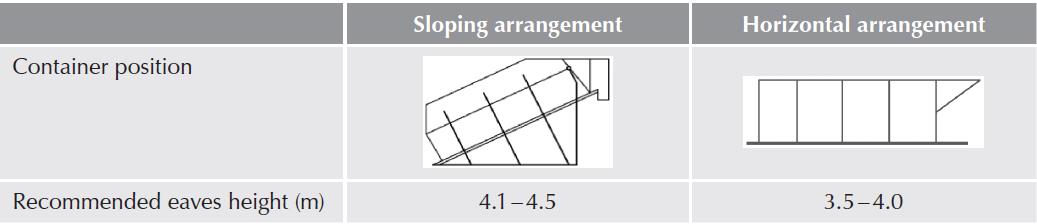

- Eaves height: influences the position and height of the stock containers depending on the equipment used (include sufficient space for filling in your plans!) (table 5)

Figure 8 shows two examples of arrangement variants of the stock containers.

Climate control and weather protection

- Protection against thermal radiation (sandwich panels, solutions with roof boards)

- Protection against rain, snow, wind and birds (pusher gates, roller gates, nets)

➝ Take access routes into account! - Ensure ventilation in summer

Floor design

- Smooth, flat paved base (facilitates cleaning)

- Drainage of silage effluent and cleaning water (drainage channel to silage effluent tank; floor gradient) (figure 9)

Automatic feeding systems are characterised by lower space requirement in the animal housing, which is why old buildings with low ceiling heights and narrow feed alleys can generally use them more easily than they can cope with standard mechanisation and a feed mixer cart. Flexible conversion and new building solutions are consequently possible. As already shown in table 3, narrow feed alleys and corresponding structural savings can be achieved. If a number of different buildings are to be connected, outdoor rails and belts are to be covered over in order to ensure undisturbed winter operation.

2.4 Performance and system limits

2.4.1 Capacity

Depending on the resources of the feeding system – whether the mixer has to be filled mechanically, stock containers are available, or silage components can be unloaded from tower or deep silos – different results regarding the number of feed mixes and the frequency of feed dispensing are to be expected. Feeding methods using a stationary mixer and a separate distribution unit have a higher capacity as regards the number of animals to be fed and the formation of performance groups than a system with a combined mixing and distribution cart. This is because while one ration is being delivered, the stationary mixer can already be producing the next feed mix. The following further factors determine the capacity of the system:

- Drive system (take the required charging times into account for accumulator-powered systems)

- Distance between feed kitchen and the groups to be fed as well as individual animal housing buildings

- Number of groups to be fed

- Frequency of feed dispensing per day

- System-related settings

According to the information supplied by manufacturers, up to 300 cows can be supplied with a stage II feeding system – if a maximum of about 15 groups and approx. 10 components are to be fed in one ration. These statements are to be viewed critically and the conditions on the individual farm should be examined. For example, on large farms with over 1,000 cows feeding systems with a stationary mixer and belt distribution are more likely to be used. Here, however, the combination of a number of rail-mounted or mobile mixing and distribution carts would be conceivable.

2.4.2 Hygiene

As with the feed mixing carts, in the case of automatic feeding systems attention must be paid to strict hygiene conditions in the plant. The duration of feed storage should be adapted to the stability of the silages and the prevailing outdoor temperatures. For example at high temperatures in summer daily stocking of the silages in the containers is to be recommended, or in the case of inadequate silage quality even stocking twice a day. In winter the silage components can be placed in intermediate storage for at least 24 hours, however (Maier et al., 2013). Furthermore, the containers should only be topped up with fresh silage when they have been largely completely emptied. Feed residues remaining in the stock containers should also be removed regularly (two to three times a week) in order to avoid any strains on the feed hygiene. Poor quality silage can lead to impairment of animal health and represents an avoidable source of emissions. In order to minimise the food base for rodent pests, the feed kitchen should be cleaned weekly (brushed clean, stock containers to be cleaned with high pressure cleaners). For this reason the floor should be designed as described under point 2.3 (Figure 9).

Furthermore, the design and position of the stock containers is crucial for cleaning. If the containers are arranged at an angle, sufficient height must be included in the calculations to enable feed residues to be removed below the container. Horizontal positions of the stock containers especially require high tightness of the containers in order to avoid crumbling losses. Individual manufacturers offer a technical option for removing feed residues carried along on the scraper floor. A flap at the front end of the stock container and a scraper integrated there aim to allow removal of the residues (Figure 9). However, it should be pointed out that cleaning of the stock containers takes up some time for the farmer and there is a need for manufacturers to optimise facilities in this respect.

2.4.3 Software (Management)

Depending on the system, the manufacturers offer a range of software solutions. However, the call for ISOagriNET-compatible systems is increasing. This should make cross-manufacturer data transfer and cross-system documentation of all technologies available in the animal housing (e.g. automatic milking system, automatic feeding system, slat cleaning robot, ventilation equipment, …).

Most of the input displays on the distribution unit make it possible to enter rations, feeding frequencies and times, and group divisions. Furthermore, manufacturers offer coupling with feed management software and animal housing computers as well as access to systems via smartphones. A standard feature of all systems is an alert to the farmer via text message or telephone call in the event of malfunctions. The information about malfunctions occurring and feeding data can be viewed and secured in separate lists (log-files).

2.4.4 Safety at work

Automatic feeding systems are characterised by great variability of the possible combinations of individual components. The systems can either be procured completely from one manufacturer, or individual system components can be purchased from different suppliers. In the latter case the question of areas of responsibility and liability in the event of loss or damage arise. Although the manufacturers issue declarations of conformity for each component of the system, in the event of a claim it must be clarified who is now liable – the operator (farmer), the manufacturer, or the firm of electricians that connected the system to the power supply. This should be clarified at a joint meeting with the responsible employer’s liability insurance association and the manufacturers and installation firms involved in operation prior to installation and commissioning of the system. The various consultants can point out safety risks in the system in advance and enable construction to be adapted. The following potential sources of danger can be avoided by appropriate planning:

- Conveyor belts should be closed on the bottom side by sheet metal panels and prevent easy access.

- Stock containers should be closed at the bottom so that there can be no danger for individuals due to circulating chains.

- Stock containers should be closed at the front side to such an extent that persons standing upright cannot reach into them easily.

- Appropriate safeguards must be provided for the mixing device (e. g. stationary mixer) and if possible these should not be installed at ground level in order to prevent the risk of individuals stumbling.

- A number of “emergency off switches” should be placed at important positions on the installation and in the feed kitchen so that in the event of an emergency the feeding system can be stopped as quickly as possible.

- The distribution facility must be equipped with a safety device that triggers stopping of the unit in the event of defined resistances. Otherwise the distance between unit and floor must be large enough (> 0.5 m) for the distribution cart to be able to run over e. g. a person lying on the ground without any harm.

3. Important planning tips

The most important aspects for planning an automatic feeding system are summarised below.

Feeding system

- Select a feeding system to match the farm

- Enable the creation of any number of performance groups

- Allow for the possibility of feeding all animals on the farm

- Ensure that suitable unloading equipment is available

- Plan the number of stock containers and sufficient storage capacity

- Select the mixing system to match the feed components

- Provide an alternative method of feeding in the event of failure of the equipment

- Take measures to prevent accidents

Feed shed

- Select an arrangement to match farm work cycles (external, eaves side or gable side development)

- Select dimensions (space requirement for equipment, building and eaves height)

- Arrange for climate control and weather protection

- Design the floor appropriately (smooth, solid base with the possibility of draining silage effluent and cleaning water)

Other structural aspects

- Consider the possibilities of expanding the animal housing and the feed shed

- Select the feed alley width (depending on the system)

- Comply with structural requirements (load bearing capacity of the structure, separate load-bearing system)

4. References and further reading (in German)

LfL-Information “Automatisches Füttern im rinderhaltenden Betrieb”. Informationstag. Ed. Bayerische Landesanstalt für Landwirtschaft. 18 February 2014, Grub. Available at: http://www.lfl.bayern.de/publikationen/informationen/062327/index.php

LfL-Information “Automatisches Füttern im Milchkuhbetrieb”. Informationstag. Ed. Bayerische Landesanstalt für Landwirtschaft. 06. Februar 2014, Grub. Available at: http://www.lfl.bayern.de/publikationen/informationen/040285/index.php

LfL-Schriftenreihe “Tierhaltung in Bayern – Quo vadis?” Landtechnisch-bauliche Jahrestagung und Eröffnung der Lehrschau. Ed. Bayerische Landesanstalt für Landwirtschaft. 25. Oktober 2011, Grub. Available at: http://www.lfl.bayern.de/publikationen/schriftenreihe/041013/index.php

Tagungsband der 11. Tagung Bau, Technik und Umwelt in der landwirtschaftlichen Nutztierhaltung, 24. – 26. September 2013, Vechta.

55 Antworten zur Automatischen Futtervorlage beim Rind (2012). Ed. DLG-Verlag GmbH, Frankfurt am Main.

© Reproduction and transfer of individual sections of text, drawings or photos (including for the purpose of teaching) and the provision of the Expert Knowledge Series 450 in whole or in part for viewing or downloading by third parties only with the prior approval of DLG e.V., Marketing Service Department, Eschborner Landstraße 122, 60489 Frankfurt am Main, Germany, tel. +49 69 24788-209, M.Biallowons@DLG.org