Avoidance of heat stress in dairy cows

DLG Expert Knowledge 450

Authors:

DLG Committee for Technology in Animal Production

- Prof. Dr. Wolfgang Büscher, Universität Bonn

- Dr. Bernhard Haidn, LfL Bayern, Grub

- Christiane Hansen, LFA Mecklenburg-Vorpommern

- Sven Häuser, DLG e.V., Frankfurt a. M.

- Dr. Hans Joachim Herrmann, LLH Wetzlar

- Jörn Menning, LLG-LSA Iden Sachsen-Anhalt

- Dieter Mirbach (†), DLG e.V., Frankfurt a. M.

- Jakob Neumayer, Vet.SMART GmbH, Graz

- Andreas Pelzer, LWK Nordrhein-Westfalen, Haus Düsse

- Boris Perovic, DeLaval, Gallin

- Olaf Tober, LFA Mecklenburg-Vorpommern

- Peter Stötzel, LfL Bayern, Grub

- Johannes Zahner, LfL Bayern, Grub

Content

- 1. Introduction

- 2. Thermal fundamentals

- 3. Ventilation and building technology aspects

- 3.1 What is to be noted with freely ventilated sheds?

- 3.2 Avoidance of solar heat input

- 3.2.1 Roof structures

- 3.2.2 Solar protection

- 4. How can heat stress be avoided in dairy cows?

- 5. Air velocity and air exchange

- 5.1 Use of fans

- 5.1.1 What should be noted when using axial fans?

- 5.1.2 What should be noted when using vertical fans?

- 5.2 Use of tube ventilation systems

- 5.2.1 Basic system description

- 6. Cooling through water evaporation

- 6.1 Notes on sprinkler systems (low pressure system)

- 6.2 Notes on water atomisation (high pressure system)

- 7. Summary

- 8. Sources

1. Introduction

Due to their high milk yield, dairy cows often have the problem that they are unable to output their related body heat to their environment sufficiently during the summer months. All preventative building and technical options that are possible with justifiable conversion effort in the existing cow shed should be exploited to prevent stress situations from arising at high ambient temperatures. These include all measures that increase natural air exchange, increase the air velocity at the animal to a tolerable level and ensure reduced heat input into the cow shed.

The installation of additional fans and air distribution systems or the use of humidification systems can be taken into consideration as a subsequent measure once all of the structural options have been exhausted. Ultimately, the question of whether using supporting ventilation is cost-effective can only be answered at the individual farm level. Improvements in animal health and positive influences on reproduction activity must also be taken into consideration here.

The objective of this Expert Knowledge Series pamphlet is therefore to describe preventative measures as well as further techniques for avoiding heat stress in existing cow shed systems and to provide decision-making assistance.

2. Thermal fundamentals

Consideration is usually given to the following parameters in order to optimise the cow shed climate for the animals:

- Air temperature

- Air exchange

- Radiation heat

- Humidity

- Air velocity

- Temperature of the lying areas

- Air quality (dust and noxious gas content)

Cattle are warm-blooded animals that maintain a constant body temperature level over a wide temperature range by self-regulating it. A temperature gradient that causes heat transport usually exists between the core body, surface and ambient temperature. Heat output in cattle is based mainly on the following mechanisms:

- Radiation

- Conduction

- Transfer to the air flowing by (convection)

- Evaporation via respiration and the skin (evaporation)

The respective, relative shares of total heat output differ and are dependent on the animal and the ambient conditions.

Heat output through radiation is dependent on the temperature of the surfaces, the geometrical size of the radiating surfaces, their position relative to one another and their properties as ‘radiators’. Heat transport always takes place from the more powerful to the less powerful ‘radiator’. To ensure a comfortable atmosphere, the heat output through radiation should not exceed a certain level. The surface temperatures of the components surrounding the internal space must be designed so that the biologically necessary heat output is neither inhibited (heat build-up) nor accelerated (excessive cooling). Overheated roof surfaces should therefore be avoided under all circumstances (see also 3.2).

Heat output through conduction occurs as a result of direct contact between the skin surface of the animal’s body and other surfaces such as the lying areas. Dairy cows therefore like to lie down on cool surfaces that enable heat output into the ground, but avoid solid manure surfaces with high microbial activity in the case of high outdoor temperatures.

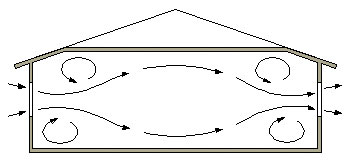

Heat output through convection is heat transport caused by the movement of liquid or gaseous particles which carry their energy along. The ‘layer of hot air’ located close to the body is removed due to the movement of air on the surface of the skin. In the summer, high air movement close to the animal can therefore foster heat output in dairy cows and reduce the negative influence of the high ambient temperatures.

The movement of the air in open cow sheds can be influenced by the wind, thermal conditions and ventilation as well as by the arrangement of components such as windbreaker nets, supporting pillars and partition walls, etc.

Heat output through evaporation is based on the following principle: when liquid water evaporates to form water vapour, energy is drawn from the environment. In the summer, this physical effect is used by animals and humans to output heat. Animals inhale the surrounding shed air, heat it and saturate it with water vapour on exhalation. As this energy comes from the lungs, heat is withdrawn from the body’s core. In animals, it can therefore be assumed that the exhaled air (expiration air) has a constant relative humidity of 95 %. In order to evaporate larger quantities of water, the animals have to breathe faster, until panting occurs as a result of heat stress. In contrast to humans, cattle are only able to output lower amounts of heat by means of perspiration.

Heat output via feed, water and excrement also forms part of thermal regulation. Animals transfer body heat to the consumed feed and water until they have reached their body temperature (38 °C). The amount of heat required for this per day is relatively low. Excretions, in which heat is also bound, are of little importance.

Physiologically, the optimum ambient temperature range for lactating dairy cows with a milk yield of 25 kg per day lies between 4 °C and 16 °C. Feed conversion is optimised in this temperature range. While feed conversion deteriorates above this range, no significant reduction in performance is to be anticipated as yet. Feed consumption and performance are only reduced significantly if these temperatures are exceeded considerably and over a longer period of time. It must be noted in this case that significant differences may occur between the individual cows depending on performance, lactation and pregnancy stage as well as acclimatisation and fitness.

Basically, direct (sensitive) heat output increases more and more as the ambient temperatures increase due to the declining temperature gradient between the animal and the environment.

In part, the cows attempt to compensate for this by physiologically increasing their body temperature by up to two Kelvin. Beyond this, further regulation is only possible by means of indirect (latent) heat output through water vapour. The unreserved availability of fresh, cool water is therefore an important prerequisite for avoiding unnecessary heat stress for dairy cows.

However, it is barely possible to increase the output of water vapour during perspiration and in the lungs. On the one side, there are animal physiological limits to this. On the other side, high relative humidity under our weather conditions often leads to the fact that the output of water vapour is only possible to a thermodynamically limited extent.

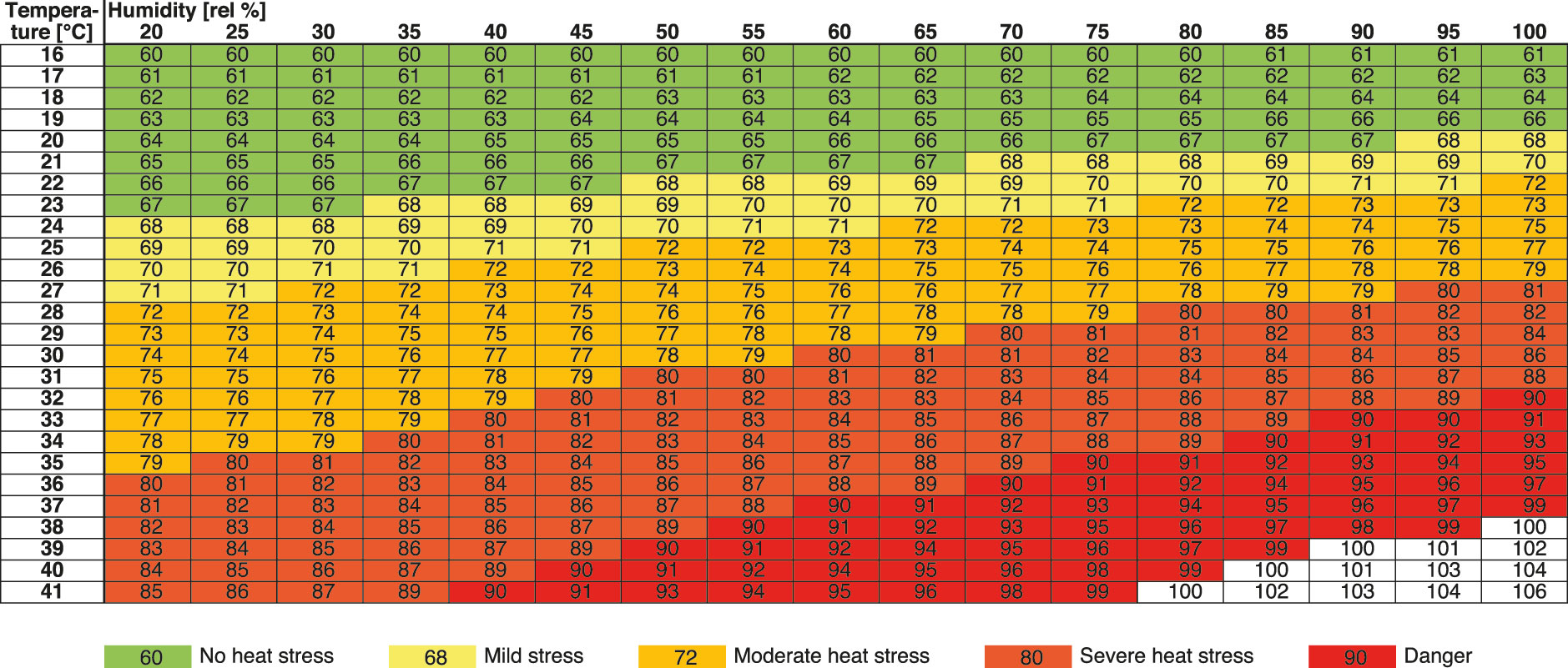

The data in the literature regarding the point in time at which dairy cows perceive heat as stress are not consistent. Exclusively listing the temperature as a definition of heat stress conditions (> 20 °C to > 25 °C) almost certainly falls short. The presumed effect on humans and animals can be assessed more reliably using a combination of temperature and relative humidity. The empirically backed results for dairy cows are shown in Figure 1. At the humidity of around 70 % usually prevalent in Central Europe, mild heat stress begins as of 22 °C; downturns in performance can already be anticipated as of 24 °C.

An important physiological value in this context is the heat content of the air, what is called the ‘enthalpy’, for which the temperature and the water vapour content of the air are crucial. The ‘Temperature-Humidity Index’ (THI) is therefore used as an indicator of heat stress in cattle/dairy cows. This index is calculated from the temperature and the water vapour content of the air. Mild heat stress for the animals begins at values over 67. The numbers in the table fields in Figure 1 show the index values calculated at the respective temperatures and relative humidities. A medium milk yield is assumed for the animals.

Indications of heat stress are also easily noticeable by attentively monitoring the animals:

The animals are recognisably suffering from stress when

- their respiratory frequency is significantly increased

- they ‘pump’ while lying down

- they lie down more rarely and stand in the aisles for a long time

- they prefer to remain at open doors and drinkers

- their body temperature increases

The animals are suffering from significant stress when

- they pant with their necks extended and their mouths open and also exhibit extensive salivation

- their feed consumption decreases (10 to 25 %)

- their milk yield decreases after around three days

- their mating activity is reduced

3. Ventilation and building technology aspects

The primary task of the ventilation system in the summer is to transport heat, humidity and noxious gases out of the cow shed in order to offer the animals pleasant ambient temperatures. Just like in the winter, a dynamic equilibrium temperature resulting from ‘heat losses’ and ‘heat inputs’ also arises in the summer. However, heat is not only generated by the animals; energy input by the sun via facade openings and indirect inputs due to heated roof surfaces can also cause significant heat inputs.

In general, the possibilities of free ventilation that are available in the location and at the building should primarily be used. If these are not sufficient, additional air circulation, air inlet and/or air outlet systems must be used.

3.1 What is to be noted with freely ventilated sheds?

The greater the air exchange, the more the interior and exterior temperature are equalised. The heat that has to be removed is not only produced by the animals but also frequently by transparent, heated roof surfaces in the summer. The facade openings should therefore be as large as possible in the summer. Simulations have shown that the openings should be no smaller than 2.5 m²/cow in total. This corresponds to a facade opening of 1.25 m²/cow and side in the case of open facade surfaces that are ideally located opposite one another. Facade openings above and beyond this dimension only lead to slight improvements.

Table 1: Empirical values for the air inlet and outlet areas for dairy cattle sheds with cross-ventilation (functional principle shown on the right)

Air exchange is fostered by a building orientation transverse to the main wind direction. However, careful checking is required to determine whether high wind speeds are to be anticipated on hot days and at high outside temperatures. If this cannot be guaranteed, consideration should be given to an adequate additional ventilation and/or cooling system when planning the cow shed. The usual wind maps usually only indicate average wind forces per month at high altitudes, and are therefore of little help for this question.

The flow through the cow shed is also influenced by the building geometry. Long and narrow buildings usually have a larger percentage facade area in relation to the floor area than broader buildings. Annexes such as milking parlours directly on the cow shed building should be avoided, as they limit air exchange.

Keeping the temperatures inside the cow shed below the outside temperatures without technical measures is only possible with a high, additional buffer mass using heavy interior and enveloping components in combination with high air exchange during the night. This also necessitates the most generously dimensioned facade openings possible.

3.2 Avoidance of solar heat input

3.2.1 Roof structures

The different roof structures and roof colours extensively influence the heat input into a cow shed. The warmer the inner side of the roof and the darker the roof colour, the higher the heat input into the interior as a result of radiation. In the air, the spread of radiated heat is extensively unhindered, as a result of which the distance between the heated roof surface and the cow shed floor, and therefore the height of the building, only play a minor role.

The orientation of the roof surface to the sun and the degree of absorption are essential to the volume of energy absorbed by the roof structure. The darker and rougher a surface is, the higher the level of absorption. The structural-physical properties of the individual roof layers influence the height of the temperature peaks on the inner side of the roof and their phase shift at the sun’s maximum irradiation.

In comparison, light, single-layer, non-insulated roof structures consisting of tiles, fibre cement or metal sheeting exhibit the highest temperature peaks. Temperatures of up to 80 °C (measured on the inner sides of sheet metal roofs) are possible depending on the orientation and absorption level of the roof surface, and should be avoided under all circumstances. The temperature peaks occur almost simultaneously with the maximum irradiation and therefore air temperature outdoors.

Double-layer, back-ventilated roof structures with wooden boarding (24 mm) or sandwich elements with thermal insulation (40 mm) remain cooler and behave approximately in the same manner. Slight phase shifts are already ascertainable here. Increased disposal or recycling costs should be taken into consideration when selecting composite materials such as sandwich elements, due to the increased difficulty of separating them by type.

Multi-layer, heavy roof structures with laminated timber ceilings (100 mm) and green roofs reveal the lowest temperature peaks and the greatest phase shifts.

Green roofs are distinctive as regards the reduction of heat peaks. They usually consist of a waterproofing membrane with a protective layer and a drainage, filter and vegetation layer on top. During rainfall or irrigation, the drainage and vegetation layers absorb water, which is output into the atmosphere again by means of evaporation via plants and the substrate. As a result of this, the various layers in the roof structure are cooled through evaporation without influencing the humidity in the interior of the cow shed. Usually, additional thermal insulation is no longer required in the roof of cow sheds, as a result of which this cooling effect can be used for the interior. At the same time, the vegetation layer significantly influences the absorption level of the roof depending on the cover and plant species. Depending on structure, a green roof can also contribute to the accessible buffer mass of the interior and therefore exert an additional, positive influence on the temperature peaks inside the cow shed in combination with cooling during the night. So that the high mass of the green roof is coupled as effectively as possible to the interior, the roof boarding material should have the highest possible thermal conductivity and not be too thick. The usual wooden boarding has proven worthwhile in this regard. Thicker wooden boarding (> 40 mm) or laminated timber ceilings are therefore not to be recommended beneath a green roof structure. With laminated timber ceilings beneath a green roof, there is also a risk that moisture which enters the timber cross-section during construction cannot dry out again quickly enough due to the large cross-section.

3.2.2 Solar protection

The direct and extensive entrainment of sunlight into the cow shed via facades, roof ridges or skylights should be avoided. Otherwise, temperature increases of four to five Kelvin can occur on the irradiated body, including the cows’ skin. Increases in excess of ten Kelvin are actually possible if the sunlight enters the cow shed directly through corrugated light panels.

Adequate roof overhangs on the facades significantly reduce solar energy input without affecting air exchange. Careful planning of the sun protection or roof overhang is required in this case, particularly for facade surfaces facing east and west, due to the low position of the sun in the morning or afternoon with high radiation power.

Large lighting ridges are more difficult to design with shading than facade surfaces. If a lighting ridge is used, it should always be ensured that direct sunlight on the animals is avoided by using light-refracting material, for instance. Large skylights are usually unnecessary in the case of long, narrow structures with low building depths, generously dimensioned facade areas and no disturbing annexes, because the natural lighting via the facade areas is sufficient.

Depending on design, photovoltaic or solar thermal panels mounted on the roof surfaces can also have a positive effect on the heat input into the interior of the cow shed via roof surfaces, as their effect is similar to that of a multi-layer roof structure. The lower the surface temperature on the inner side of the panels and the higher the volume of air that flows through between the panel and the roof surface, the lower the heat input onto the roof surface.

In windless conditions, a ventilation ridge only influences air exchange to a minor extent in the summer due to the approximately identical air temperatures in the interior and on the exterior during the day. Nevertheless, the majority of cattle sheds are built with an open ridge in order to foster the removal of noxious gases and humidity in the case of extensive differences in air temperature between the interior and the exterior in the winter.

Structural recommendations for reducing heat stress

- Cow shed positioned transverse to the main wind direction

- Cow sheds that are not excessively wide

- Largest possible ventilation openings located opposite one another

- Adjustable windbreaker grilles/curtains for optimising air inlet and air outlet areas in the summer

- Avoidance of annexes that inhibit ventilation

- Unimpeded flow onto the cattle shed on the land

- Avoidance of direct sunlight into the area where the animals are located through unprotected facade and roof surfaces or light panels

- Use of light colours for the roof covering

- No single-layer, light roof structures

4. How can heat stress be avoided in dairy cows?

The ‘warm air cushion’ of the air in the cow’s coat and around its body can be broken down by generating a directed air flow in the areas in which the cows are located, thus increasing the animals’ convective heat and water vapour output. The perceived temperature is reduced as a result of this (Figure 2). The perceived temperature results from the factors of temperature, relative humidity and air velocity. Depending on the latter two factors, the animals are able to output different volumes of water via their skin. This leads to latent heat, which produces a cooling effect on the animals’ skin as of an air velocity of 1.0 m/s.

The German Industry Standard (DIN) 18910 specifies minimum air flow rates for cattle. However, these refer to closed and thermally insulated building envelopes, and do not apply to cow sheds whose design-based thermal insulation is so low that it cannot be used to significantly influence the shed air temperature. In cow sheds that offer a cooling option, the volumetric air flow in the summer can be reduced accordingly during planning. Conducting incoming and outgoing air at the same time must be guaranteed for functioning forced ventilation. Otherwise, air exchange can come to a standstill in the event of high counter-pressure (e. g. caused by wind at the exhaust air outlet).

Consequently, air exchange rates that are far higher than those specified in DIN 18910 must be implemented for cattle sheds without sufficient thermal insulation in the summer. These must be determined individually for the specific cow shed under consideration of the respective occupancy.

5. Air velocity and air exchange

5.1 Use of fans

Fans are used primarily to remove the warm layer of air around the animals’ body (i. e. the convective heat output). To do this, a high air velocity in the area of the animals is desired. This can be achieved with a few large vertical fans mounted under the ceiling, what are called ceiling fans. Conversely, axial fans are arranged horizontally in succession and generate a corresponding flow through the cow shed.

In cubicle feeding pen cattle sheds, fans are used to generate air movement in the animal area when the wind velocity is insufficient at high ambient temperatures. The total fan air capacity to be installed is dependent on the length of the cow shed, the performance level of the respective cow group and the design of the roof. The recommendations for the ‘installed fan capacities’ fluctuate between 500 and 1,200 m³ per cow and hour, without taking the fans for the milking parlour and the waiting area into consideration. Measurement reports concerning fans that are suitable for use in dairy cattle sheds can be downloaded from the websites of the Bavarian State Research Center for Agriculture (LfL) and the Higher Federal Learning and Research Institute for Agriculture (HBLFA) Raumberg-Gumpenstein using the following links:

- https://www.lfl.bayern.de/cms07/publikationen/informationen/127543/index.php

- 13 Ventilatoren zur Kühlung von Rinderställen – PDF free download (docplayer.org)

Irrespective of which technology is selected, automatic, temperature-controlled switching of the fans should not be forgone, as the subjective perception of the cow shed climate by the support personnel and what the animals are actually experiencing never conform in the case of manual control.

5.1.1 What should be noted when using axial fans?

An arrangement above the cubicle rows is regarded as the optimum position of the fans (Figure 4). Probably the most important advantage of this is that measures for reducing the heat load are supported precisely where the animals are intended to remain the longest. It additionally prevents the floors from being dried off too quickly by the fan. Various fans that operate with time control, have a short throw and are therefore able to concentrate their effect on the lying area or other areas are currently available on the market.

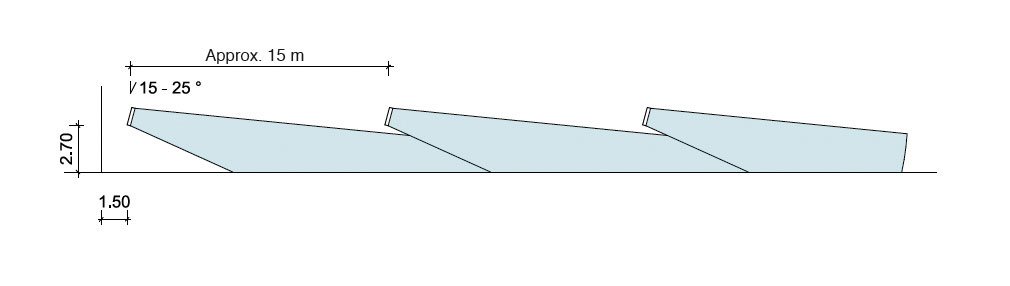

The spacing between the fans depends extensively on the throw of the fan, the installation height and the inclination angle. Refer to the LfL measurement report for the basic data. If the fan is mounted with the lower edge of its frame at a height of 2.70 m above the lying surfaces, a protective grille can be forgone from the point of view of the employers’ liability insurance association. This makes the necessary cleaning and maintenance work considerably easier. The first fan should be installed directly in the gable wall or 1.50 m (minimum fan diameter size) away from the gable wall. This minimises the counter-pressure (‘suction resistance’). If it is possible to install the first row of fans in the gable wall, fresh air can additionally be input into the cow shed from the outside. In this case, however, the fan must be protected against precipitation and direct wind.

An installation angle of 15 – 25 ° has proved suitable. The angle is dependent on the installation height and the throw. The angle should always be adapted individually for each cow shed with the assistance of a smoke generator so that the air flow hits the animals and does not flow over them (Figure 3).

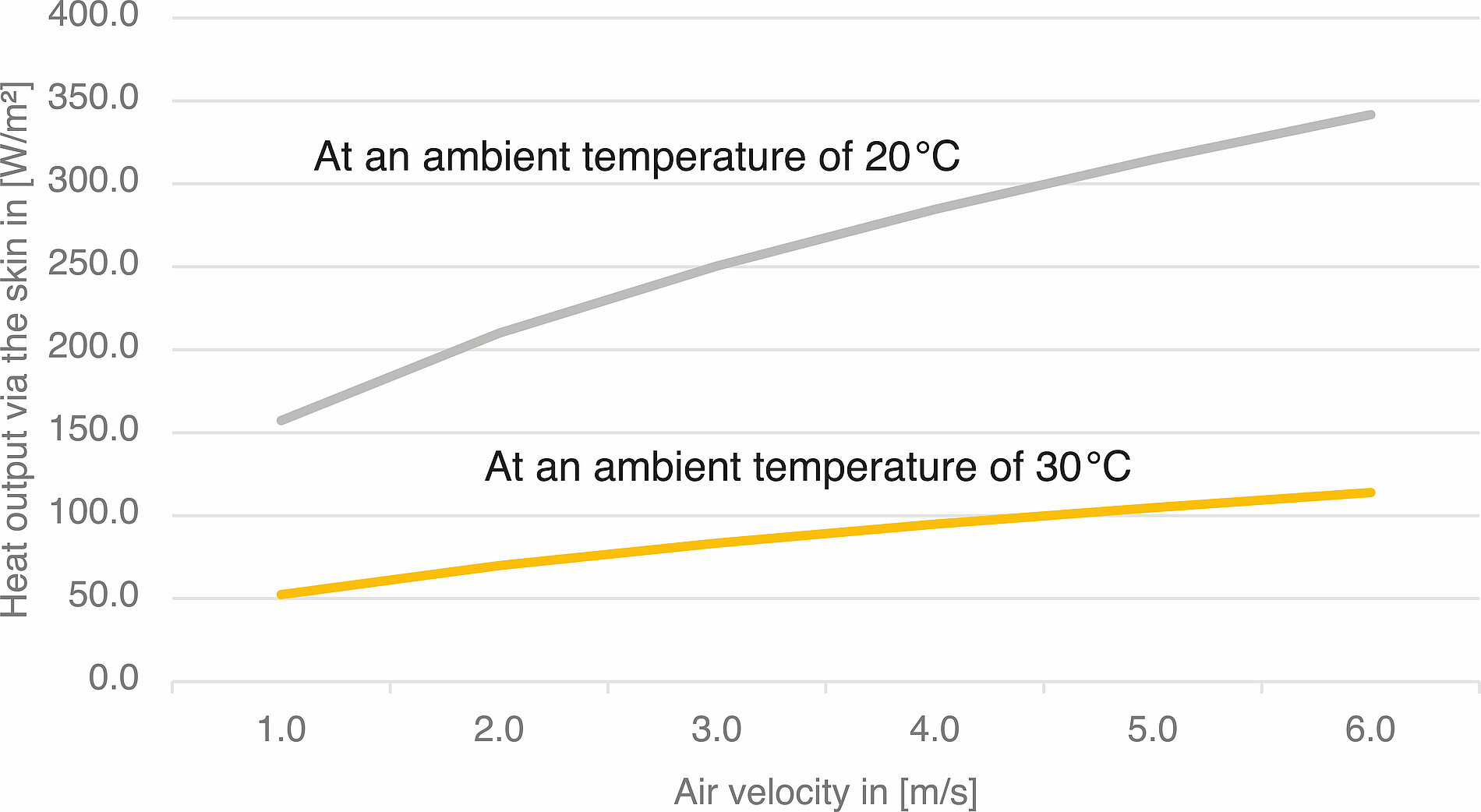

Arrangement of the fans for generating a ‘circular flow’

Axial fans can also be arranged so that the air moves horizontally in a circle in the cow shed (Figure 5). Here, the aim is for the air in the building to circulate in windless conditions. However, the effective removal of heat, humidity and noxious gases is limited with this system.

Arrangement of the fans for generating a transverse flow

A third option for positioning axial fans in the cow shed is the transverse arrangement (Figure 6). This arrangement enables transverse ventilation to be supported at a low wind velocity. Compared to the longitudinal orientation, more fans are needed with this arrangement in order to achieve the most consistent flow possible through the building. Another disadvantage is the extensive flow over the floors.

If supply or exhaust fans are only switched on intermittently, i. e. as needed, in a freely ventilated cow shed and then generate a room flow that differs significantly from the transverse ventilation, this is referred to as ‘combination or hybrid ventilation’.

Recommendations for the use of axial fans (with horizontal throw direction)

- Arrangement of the fans primarily in areas in which the animals stand closely together

- Hourly air capacity to be installed 800 – 1,200 m³/cow

- Specific power consumption (measured, not rated power) < 40 W/1,000 m³ volumetric air flow (smaller fans with a higher air jet velocity are usually less efficient)

- Arrangement of the fans above the cubicles if possible

- Protective grilles forgone if possible; mounting height at lower edge of fan ≥ 2.70 m

- Fan spacing in blowing direction depending on the fan parameters

- Fan control using thermostats (multiple series connection, rotational speed regulation)

- If residential areas are located nearby, reduce the rotational speed or switch off the fans at night

- Observe the sound pressure level (dB(A)); see HBLFA Raumberg-Gumpenstein recommendations

5.1.2 What should be noted when using vertical fans?

Ceiling fans (Figure 7) are convincing thanks to their low specific power consumption (0.3 – 1.5 kW) and their low noise level of less than 60 dB(A) due to their low rotational speed of 75 – 140 rpm. However, their variability in terms of their installation location is limited. According to the circumstances within the building and the high amount of space required by the fans, they are often installed centrally above the feeding alley, although this leads to negative side-effects such as the drying-out of the feed.

The fans can have diameters of four to seven metres and can achieve air circulation of up to 700,000 m3/h (manufacturer’s specifications) depending on design. The fan diameter is often recommended as the installation height.

Ceiling fans direct the air flow vertically downwards. Focus here is on air circulation and the achievement of animal heat output through convection. Air velocities of > 2 m/s are achieved beneath the fans. Towards the cow shed wall, this decreases significantly due to cow shed fittings and the animals (wind shadow) and is < 1 m/s. Under unfavourable conditions, at high outside wind velocities, open side walls and doors can cause the flow generated by the fan and the incoming outside air to ‘work against one another’. The flow behaviour can be significantly influenced, particularly in the boundary areas of the cow shed that are located close to the outside air. The air velocity generated in cow sheds with closed walls is higher than that of cow sheds with open walls, as the air circulates better in the cow shed.

Recommendations for the use of vertical fans

- Large vertical fans not arranged above the feeding alley located centrally in the cow shed (drying-out effect on the feed)

- Switching on the fans recommended as of a cow shed temperature of 16 °C

- Low noise level enables use even in the vicinity of residential areas

- Wind movements outside of the cow shed can extensively influence the flow behaviour in the boundary areas of the cow shed in the case of open side walls

- Not to be used in cow sheds in which there is a risk that heated air from the back-ventilation level of the roof or, with single-layer structures, warm air from the roof space is pushed into the animal area

5.2 Use of tube ventilation systems

5.2.1 Basic system description

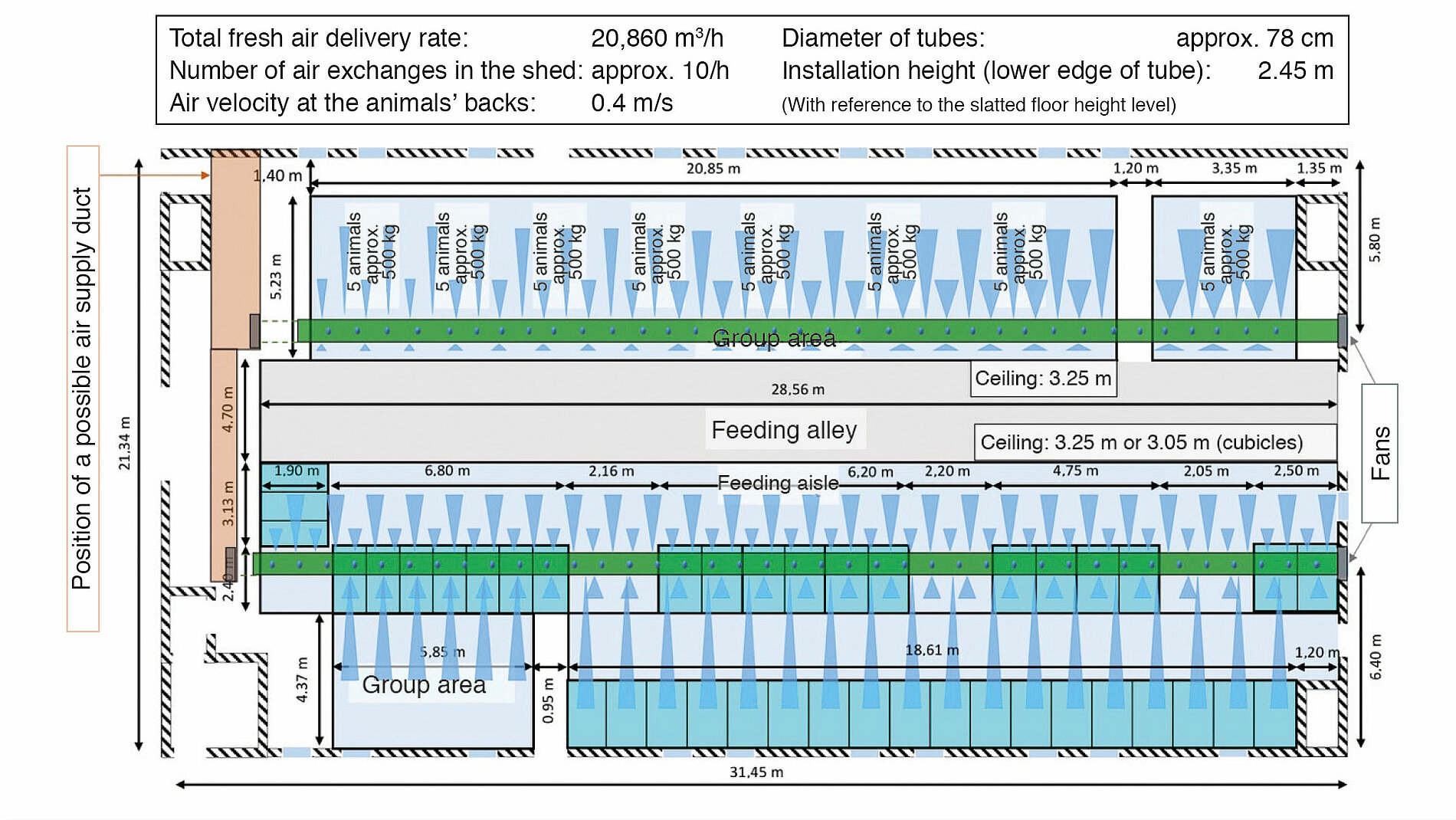

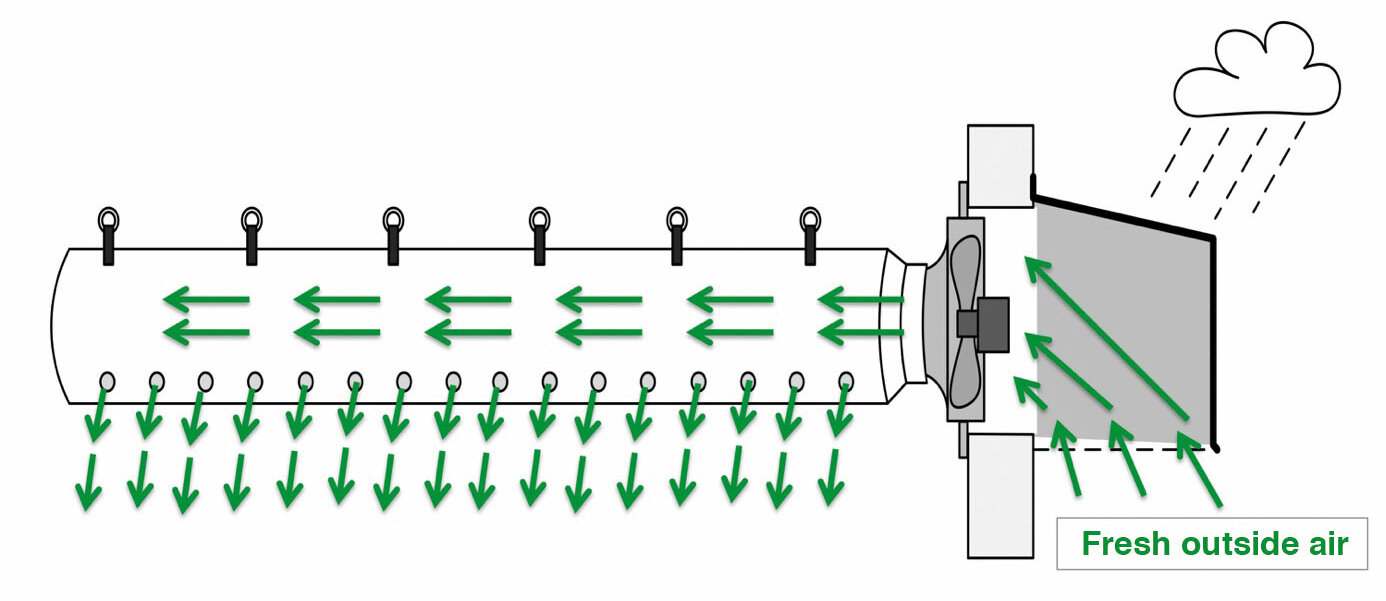

The use of tube ventilation systems is another method of conducting incoming air into dairy cattle sheds. The system functions according to a positive pressure principle, which is shown in Figure 8.

In this process, fresh outside air is forced into an air-tight textile tube (usually made of polyester fabric) by means of a fan selected according to the desired air exchange in the area of the animals. The fresh air is distributed over the animals through small air outlet holes in the textile tube according to the requirements of the cow shed. The geometry and the specifications of the individual ventilation tubes have to be calculated specifically to accomplish this. The more precise the underlying calculation process, the better the requirements in the cow shed can be met.

Air velocities of up to 4 m/s can also be generated on the animals’ backs with tube ventilation systems, as a result of which heat stress is primarily avoided. As in the case of other ventilation systems, another objective is the improvement of the air quality through continuous air exchange. With regard to the avoidance of heat stress, these systems therefore also serve to remove the warm and usually humid, low-oxygen shed air. This reduces the cow shed temperature and/or the humidity in the shed. In the waiting area and in the feeding alley, the system can be used to input fresh air between the animals from above.

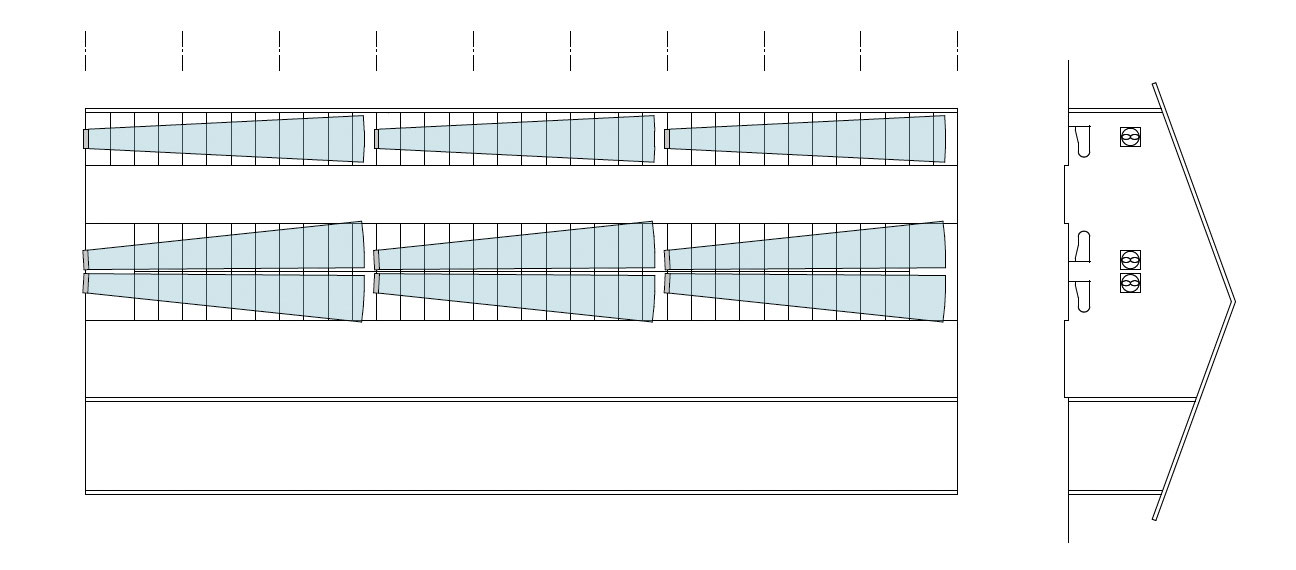

Figure 9 schematically shows the position of the air cones when cooling two rows of cubicles. The intention of focussing the direct fresh air supply exclusively on the area of the individual rows can clearly be seen.

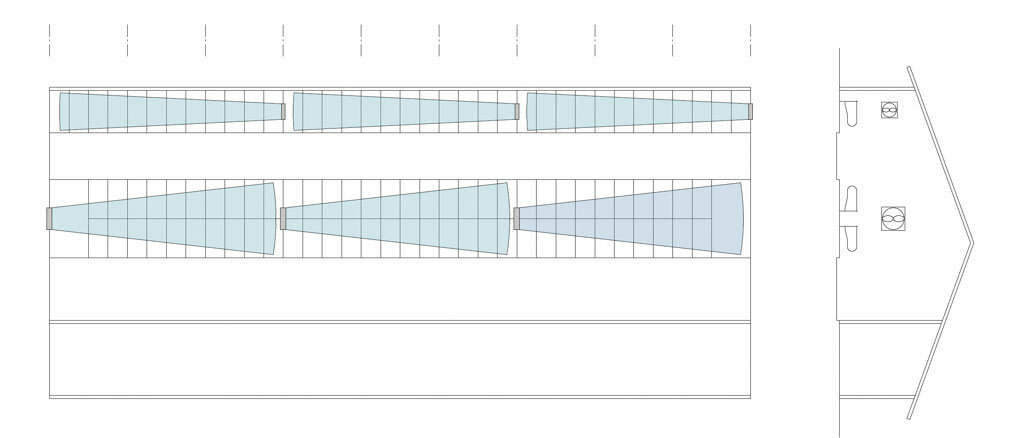

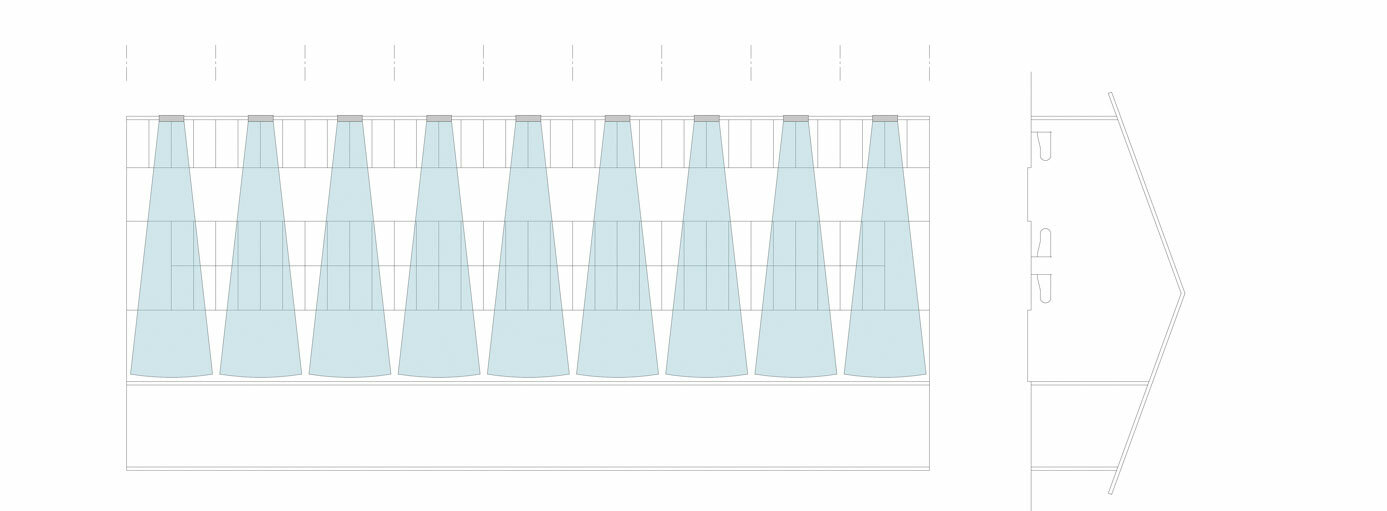

The fresh air cone distribution shown in Figure 10, with precisely one cone per cubicle, is used to generate a consistent cooling effect in all identical, animal-specific areas, which is intended to lead to the ideal distribution of the animals over all of these areas. This is aimed at preventing the animals from gathering in climatically outstanding locations in the cow shed (e. g. the side opening in the main wind direction), as is frequently observed at the height of the summer.

Tube ventilation systems can significantly reduce heat stress through higher air exchange rates, particularly in low buildings with few natural incoming or outgoing air areas and in areas with low natural air movement. Unlike natural ventilation, tube ventilation systems are designed for local air exchange rates. In this case, local means that only air volumes which are actually used by the animals are taken into consideration. Air flows three metres above the animals, for instance, only have a minor influence on the climatic conditions in the area near to the animals. The situation is similar with wide feeding alleys, straw beds, etc. according to the manufacturers’ specifications, 10- to 20-fold air exchange per hour is desired for tube ventilation systems for dairy cows.

Figure 11 shows an example of the arrangement of the tubes in the cow shed (according to the manufacturers’ specifications) to ensure consistent supply air distribution in the cows’ cubicles.

Correct calculation of a tube distribution system is very complex and necessitates relevant experience. Consequently, the use of self-fabricated supply air tubes is advised against.

Recommendations for the use of tube ventilation systems

- Use particularly in low buildings (e. g. poorly ventilated old buildings) and/or areas with low natural air movement. Also suitable for the waiting area

- Systems operate 100 % with fresh air and generate a consistent supply of fresh air in all animal areas

- Reduction of humidity and noxious gases in the cow shed

- Air velocities can be adapted to the animal weight

- Tube ventilation systems can only be regulated in a limited fan output range

- Individual design and calculations specific to the cow shed necessary

- Outgoing air areas must always be present and taken into consideration in the calculation

- Systems are cow shed-specific and cannot be adapted without a great deal of effort in the event of cow shed modifications

- Extensive influence of external wind can negatively affect the function of the system

6. Cooling through water evaporation

A distinction can be made between two methods when using water to overcome heat stress in dairy cows:

- Low pressure system: direct ‘sprinkling’ or ‘watering’ of the animals’ bodies (e. g. in the feeding area)

- High pressure system: ‘spraying’ or ‘atomisation’ of water for evaporation (e. g. in the waiting area)

In the first method, the animals are wetted directly with water, as in ‘taking a cold shower’, with the result that body heat is also transported away along with the outgoing water, which simultaneously cools the skin. Body heat is also removed when water evaporates on the coat. The additional use of fans can support this process.

In the second method, the air temperature is lowered by means of water evaporation. During this ‘adiabatic cooling’, the water vapour content in the air increases, whereby the air temperature is lowered. As the heat content of the air remains the same, however, this does not really lead to any physiological relief for the animals at a high relative humidity (> 80 %) (as explained in Section 2).

At low to medium humidities, the combined use of water and fans is the most efficient method of cooling the cows.

6.1 Notes on sprinkler systems (low pressure system)

Sprinkler systems (Figure 12) can be installed in various locations in the cow shed, e. g. in the open-air area, in the waiting area, in the feeding area or above the alleys. Installation in the open-air area has the positive side-effect that it is made more attractive for the animals.

If no outdoor areas are available, sprinkler systems should be installed in a location in the cow shed in which the animals can move sideways into the sprinkling area. The animals avoid getting their ears wet. If a poor location is chosen, it may occur, for instance, that passages are completely blocked and animal traffic is restricted as a result. Besides the correct choice of location, the water droplet size and velocity also exert a significant influence on the acceptance of sprinkler systems.

15-minute intervals have proved suitable for operation, whereby water is sprayed for about three minutes, controlled by a timer, followed by an evaporation time of twelve minutes. Approximately one litre of water per square metre of surface area can be sprinkled in this process.

6.2 Notes on water atomisation (high pressure system)

In high pressure systems, the water is very finely atomised (Figure 13). The water droplets should already evaporate in the air so that the walking and lying areas are not wetted unnecessarily (walking safety). The requirements made on the technology are very high in order to ensure nebulisation into fine droplets. The very fine water nozzles (pre-filtered and purified water, calcification!) and the high water pressure necessitate increased maintenance effort and energy input.

Conversely, the water consumption is lower than that of low pressure systems. Humidity monitoring and the interruption of cooling system operating times are a must when using high pressure cooling systems.

7. Summary

The hot summers experienced over the past few years have been a wake-up call. Heat stress in the dairy cow shed poses a specific risk with extensive economic impacts. Besides spells of hot weather, however, there are other predisposing factors that need to be taken into consideration, such as cow shed construction, cow shed design and management, since they can foster or even give rise to the risk of heat stress in dairy cows. On the other hand, heat stress can also be reduced with the right decisions and measures.

In addition, we also need to deal intensively with the biological changes related to the metabolism and milk yield as well as the increase in feed consumption and heat development in our dairy cows. Dairy farmers should obtain expert information about specific solutions to prepare themselves accordingly for the coming summers and possibly for more high temperatures.

8. Sources

- Collier et al. (2012): Quantifying Heat Stress and Its Impact on Metabolism and Performance; Department of Animal Sciences, University of Arizona.

- DIN 18910: Wärmeschutz geschlossener Ställe – Wärmedämmung und Lüftung – Planungs- und Berechnungsgrundlagen für geschlossene zwangsbelüftete Ställe; Ausgabedatum 2017-08.

- HBLFA Raumberg-Gumpenstein (2019): 13 Ventilatoren zur Kühlung von Rinderställen; Messbericht HBLFA Raumberg-Gumpenstein.

- LfL-Information (2020): Ventilatoren für den Einsatz im Milchviehstall; 2. Auflage Oktober 2020.

- Nordlund, K. V. (2008): Practical considerations for ventilating calf barns in winter. Veterinary Clinics of North America: Food Animal Practice, 24:41 – 54.

© Reproduction and transfer of individual sections of text, drawings or photos (including for the purpose of teaching) and the provision of the Expert Knowledge Series 450 in whole or in part for viewing or downloading by third parties only with the prior approval of DLG e.V., Marketing Service Department, Eschborner Landstraße 122, 60489 Frankfurt am Main, Germany, tel. +49 69 24788-209, M.Biallowons@DLG.org